We’re excited to announce the launch of Shared Reality Copilot, a groundbreaking new feature in the Shared Reality workspace that bridges the gap between 3D scans and P&ID diagrams in piping-intensive facilities.

From petrochemical plants to power stations, industrial teams often face the challenge of reconciling fragmented 3D scan data with legacy P&ID documentation. Shared Reality Copilot helps bridge this critical gap, combining advanced AI detection with human oversight to deliver highly reliable infrastructure models that support safety, compliance, and efficiency.

What Is Shared Reality Copilot?

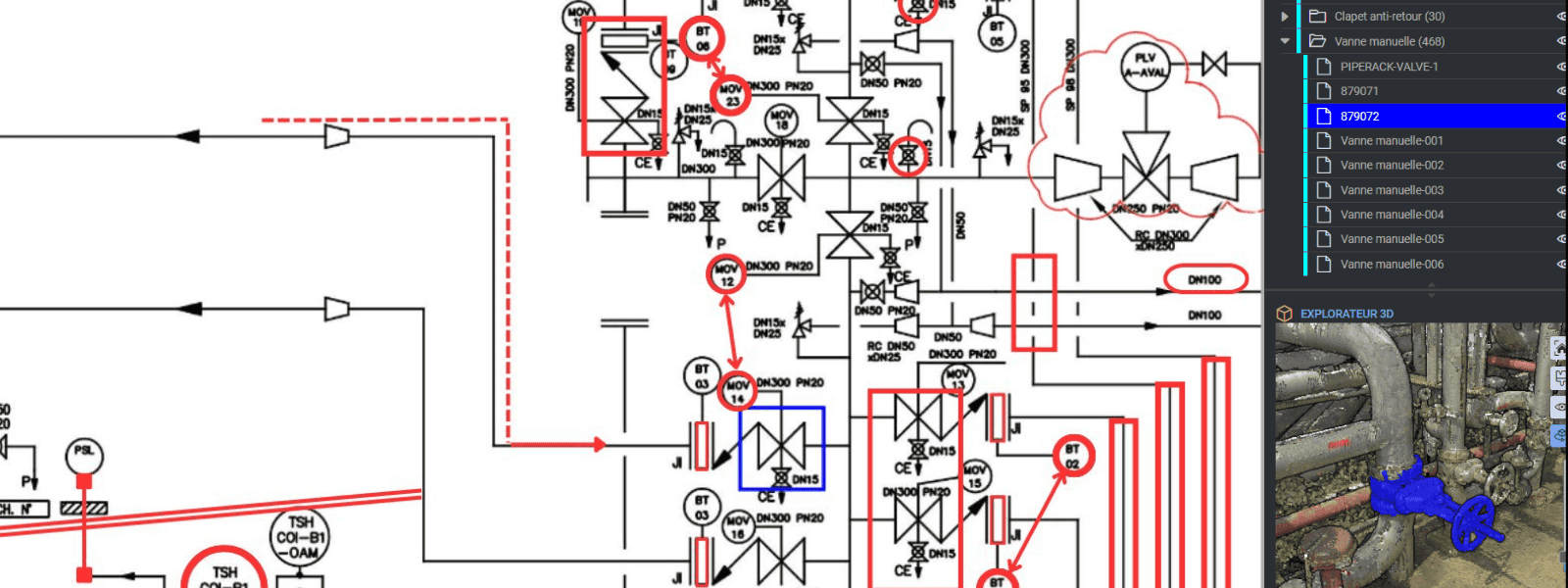

Shared Reality Copilot is your AI-assisted, human-guided partner for linking 3D scan data with P&ID diagrams. It automatically detects process equipment pipes, valves, pumps, vessels and suggests logical connections across fragmented scans and legacy documents. But here’s the key: you remain in control. Every AI suggestion is verified or corrected by the user, combining the speed of automation with the expertise of your team.

AI That Works With You,

Not Instead of You

Key Capabilities:

AI-Powered Detection of pipes and process equipment

Guided Line Tracing across fragmented scans and diagrams

Human-in-the-Loop Verification to confirm or adjust AI suggestions

Full Audit Trail for compliance, QA, and collaboration

Solving a Complex Challenge

For years, engineers, project managers, and asset owners have struggled with:

- Outdated or incomplete facility models

- Labor-intensive reconciliation processes

- Difficulty tracing systems across disconnected datasets

- Risk of error in safety-critical environments

Shared Reality Copilot addresses these issues by offering a hybrid AI-human workflow. This approach ensures teams can create reliable models without sacrificing speed or quality.

“Copilot transforms the way teams connect the physical and digital worlds in industrial environments,” said Julien Villemeur, Chief Product Officer at Samp. “By automating the tedious parts and guiding users through the critical steps, we’re enabling faster project execution and safer, smarter decision-making.”