Having participated in many audits of industrial facilities by the regulator, I have witnessed several times the famous “final twist”, well-known and feared by most players in the heavy industry.The audit goes well, all questions are answered properly, demonstrations of the IT tools are performed successfully, all records and traces of corrective actions are shown.

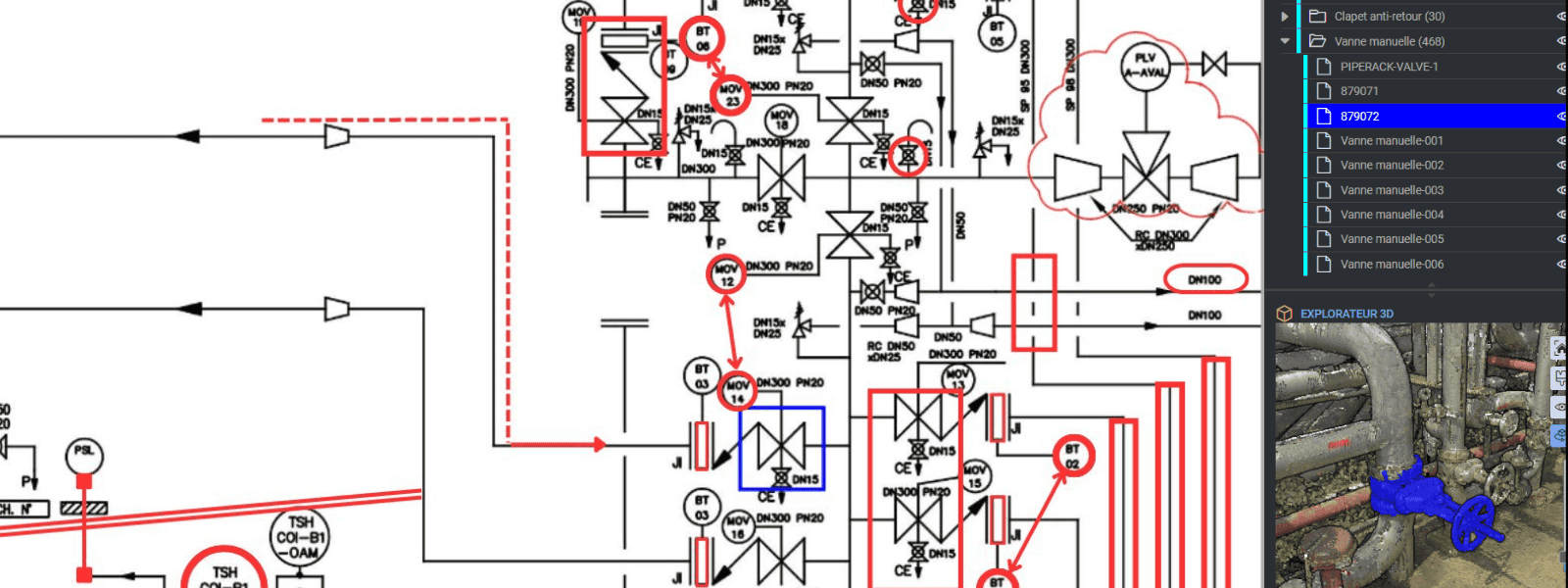

So far so good…And then the auditor asks the killer question! It usually goes something like “All your tools and processes seem very efficient, but how do you ensure they reflect the reality of all your equipment on site?”This one single question often makes the whole demonstration collapse. And for a good reason: it is almost always the missing link in all procedures for ageing industrial facilities.Industrial reality capture coupled with modern IT systems are a great support to have fully robust processes anchored in the only reliable source of truth: the field itself.Reach out to us if you want to learn more on how that can apply to your facility.

Webinar : Stop Flying Blind in Terminal Maintenance

Stop flying blind in terminal maintenance. Most turnaround issues don’t start on site, but during preparation with incomplete, outdated, or disconnected information. This teaser webinar explores how shared field reality and Document AI help teams align earlier, reduce unnecessary field visits, and avoid costly surprises before mobilization.