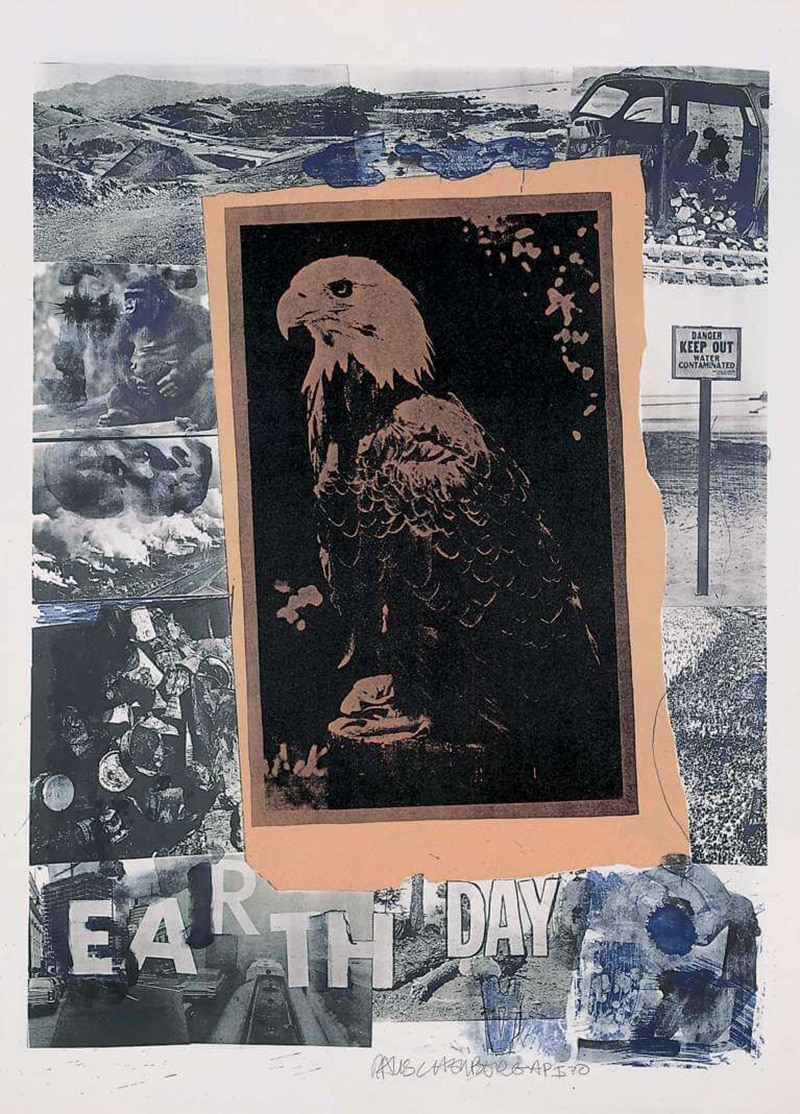

Each year on April 22, Earth Day marks the anniversary of the birth of the modern environmental movement in 1970.

The fight for a clean environment continues today with increasing urgency as the consequences of climate change and resource depletion become more evident every day.

Earth Day is now widely recognized as the world’s largest environmental celebration, involving more than one billion people each year in a day of action to change human behavior and create policy change at the global, national and local levels.

Earth Day is now widely recognized as the world’s largest environmental celebration, involving more than one billion people each year in a day of action to change human behavior and create policy change at the global, national and local levels.

The concept of sustainable development formed the basis of the United Nations Conference on Environment and Development held in Rio de Janeiro in 1992. This summit marked the first international attempt to develop action plans and strategies to move towards a more sustainable development model.

“Sustainable development is development that meets the needs of the present, without compromising the ability of future generations to meet their own needs.”

In September 2015, the United Nations General Assembly adopted the 2030 Agenda for Sustainable Development, which includes 17 Sustainable Development Goals.

![]()

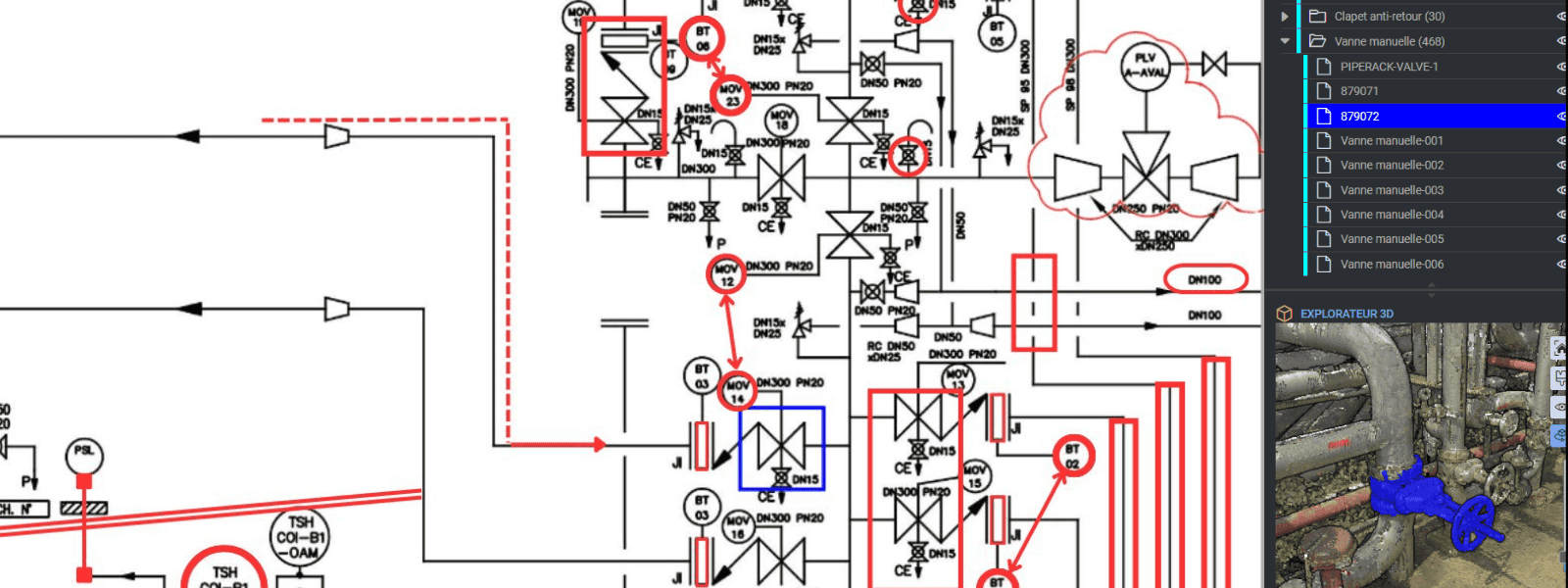

At Samp, we mainly focus on Goal #9, “Industry, Innovation and Infrastructure”, which includes among its targets the following: “By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities”

This specific target means that most large industrial facilities must adapt to enable decarbonization and to improve materials circularity, while using less harmful reactants.

Carbon-intensive industrial processes need to be replaced with decarbonized electrified processes. At the same time, raw materials feedstock is gradually substituted by a more variable – and therefore more complex – feedstock of recycled materials.

At Samp we want to be the catalyst of this sustainable transformation. We help industrial facilities successfully go through an accelerated pace of modernization and meet the fundamental challenges of safety and efficiency.

We have crafted a simple solution that reduces the gap between the as-built and as-documented condition of an industrial facility, improving all stages of plant turnarounds, including handover to operational teams.

The engineering studies and project execution required to transform industrial facilities can now be conducted with more certainty, reducing the environmental impact of the industry more quickly.

Helping to accelerate the reduction of energy and carbon footprint at existing industrial facilities, while improving their ability to use circular raw materials and less harmful reactants is our humble contribution to sustainable development. We believe in it, we are already witnessing the results.

Happy Earth Day 2022 !

Do you want to continue the conversation and take action? Get in touch with Samp!

https://www.rauschenbergfoundation.org/art/art-context/earth-day

https://www.earthday.org/history/

http://www.sd-commission.org.uk/pages/history_sd.html

http://www.sd-commission.org.uk/pages/what-is-sustainable-development.html

https://www.un.org/development/desa/disabilities/envision2030.html

https://www.un.org/development/desa/disabilities/envision2030-goal9.html