Contract operators navigating public tenders often grapple with uncertainties surrounding the condition of assets when managing industrial or utility facilities. Whether dealing with operations & maintenance contracts, concession agreements, or complex design-build-operate projects, accurately assessing the existing state of plants or networks is a critical factor in minimizing uncertainty and risk.

Traditionally, lengthy equipment inventories involving months of on-site inspections have been the norm, leading to high costs and time-consuming processes. However, a game-changing solution has emerged over the last four years, thanks to Samp, a france-based deeptech company.

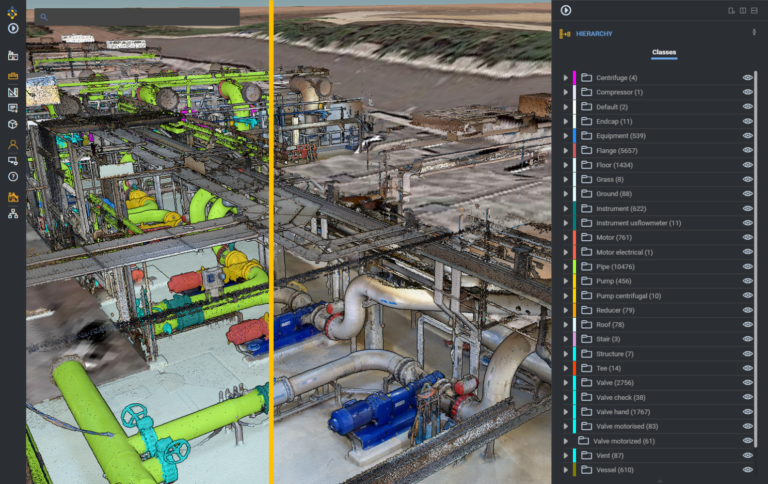

Samp’s purpose-designed AI enables automated inventories directly from 3D reality capture, eliminating the need for extensive on-site inspections. Instead of sending personnel for weeks or months, contract operators can now deploy surveying teams to capture site realities within hours or days using techniques such as smartphones, mobile laser scanners, drones, and more.

The resulting 3D scans are seamlessly processed by Samp’s AI, providing an online workspace for equipment inventory verification. This approach has drastically reduced lead times and costs, making it possible to scan thousands of square meters per day.

The benefits are substantial

- Inventory lead times and costs are significantly reduced.

- Site team risk exposure is minimized.

- Risk mitigation measures can be implemented days after contract engagement.

- The process can be conducted before issuing tenders, ensuring transparency and the lowest fair price.

- Maintaining an up-to-date inventory throughout the contract is easily achieved.

Whether dealing with oil & gas, chemicals & industrial gases, water & waste, or district heating & cooling, transitioning to AI-powered continuous inventory management offers a new paradigm for better economics, best-in-class safety, and unmatched customer satisfaction.

This isn’t a promise for tomorrow—it’s a ready-to-use solution in operation today.