Brownfield Digitalization: 3 Reasons Why CAD is the Wrong Tool

Key Takeaways Brownfield environments change faster than traditional CAD workflows can keep up. CAD is optimized for design, not for managing as-built conditions on

Key Takeaways Brownfield environments change faster than traditional CAD workflows can keep up. CAD is optimized for design, not for managing as-built conditions on

Key Takeaways Reconciliation failures create a hidden 30% gap between planned and real-world conditions. Asset reconciliation is an operational discipline, not a one-time cleanup

Stop flying blind in terminal maintenance. Most turnaround issues don’t start on site, but during preparation with incomplete, outdated, or disconnected information. This teaser webinar explores how shared field reality and Document AI help teams align earlier, reduce unnecessary field visits, and avoid costly surprises before mobilization.

Key Takeaways Surprises are the primary cause of turnaround delays and scope growth Most Surprises originate from unverified as-built conditions Eliminating Surprises requires structured

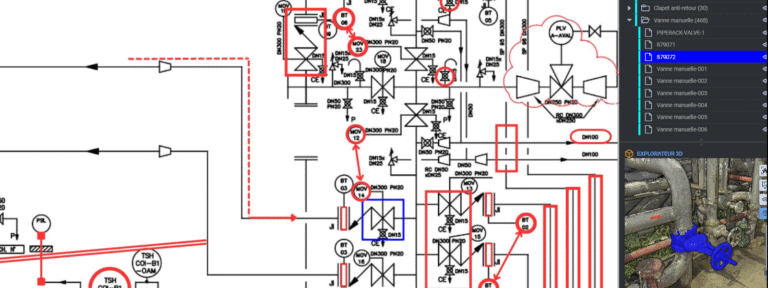

Key Takeaways Relying solely on P&IDs for industrial maintenance leaves teams with dangerous blindspots: hidden issues and missing context that can lead to surprise

Key Takeaways The Silent Financial Killer: Inaccurate inventory data is not merely an administrative nuisance; it is a primary driver of operational expenditure (OPEX) leakage,

Discover how Elengy enhanced efficiency and reliability in their industrial facilities using Samp’s Shared Reality solution. Watch the client testimonial to learn how digital transformation drives real impact in the process industry.

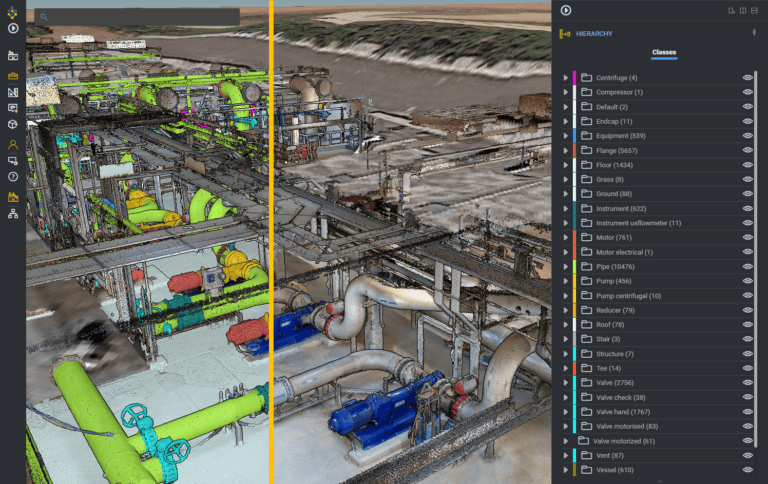

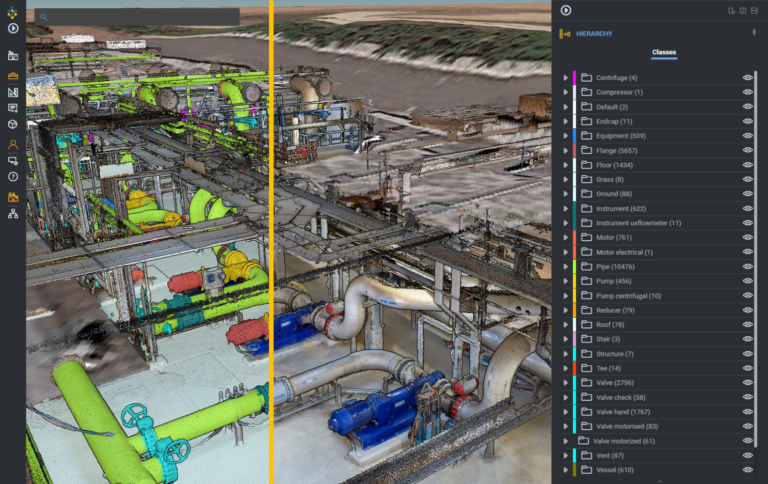

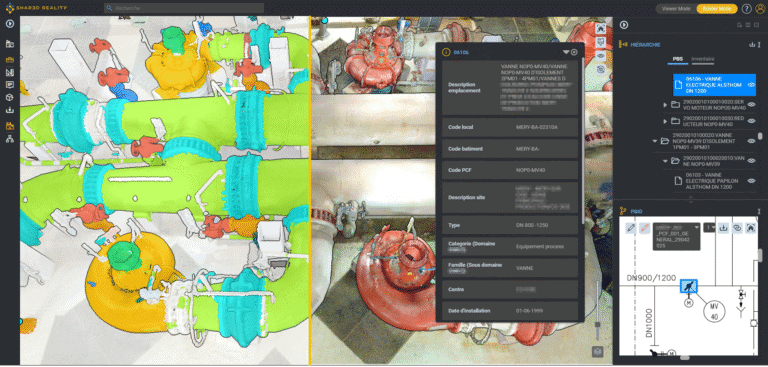

Shared Reality 2025.04 is here! This release reflects our continued focus on helping field and office teams work smarter with cleaner, more accurate data—directly within the context of real assets. From advanced equipment recognition to improved collaboration tools in 3D, every update is built to support safer, more efficient, and more informed decision-making in daily plant operations.

BIM models are excellent tools for design and construction. They help during coordination, clash detection, and structured data management. But once the construction phase is over, the models often become dead weight – complex, expensive to maintain, and irrelevant for everyday operational needs.

Discover how BRL enhanced efficiency and reliability in their industrial facilities using Samp’s Shared Reality solution. Watch the client testimonial to learn how digital transformation drives real impact in the process industry.

Agentic AI is transforming industry but only when it understands the real world it operates in. Samp’s Shared Reality bridges the gap between data and reality, creating a continuously aligned, verified view of the physical environment that empowers AI agents to act with confidence and precision.

SEDIF, the public utility supplying drinking water to 4 million people across seven departments in Île-de-France, is creating a digital twin of its extensive network-covering nearly 8,000 km of pipelines and three major production plants.

Extend the reach of your scanning services by delivering your scanning campaigns on an AI-powered 3D workspace, designed from the ground up for the industry. Leverage your surveying and topographic expertise to consolidate valuable field data into a single viewer: maps, aerial and drone orthophotos, laser scans, photogrammetry or videogrammetry, and georadar can now be securely viewed, updated and shared in one place.

Upscale the value of your engineering services offering by delivering digital twin as a service, powered by your qualified staff. Improve customer retention with longer-term contracts that ensure continuous synchronization of technical data with the as-built facility. Accelerate or automate the production of technical deliverables when working on brownfield projects with little or no existing input information.

When preparing a quote for operating a facility on behalf of the owner, be sure to maximize that short window of time by taking advantage of as much technical information as possible. Turn your initial site visit into a unique opportunity to capture the current condition of the facility. Make a bid that will beat the competition with an already operational digital twin, while giving you increased confidence in your future service contract margins.

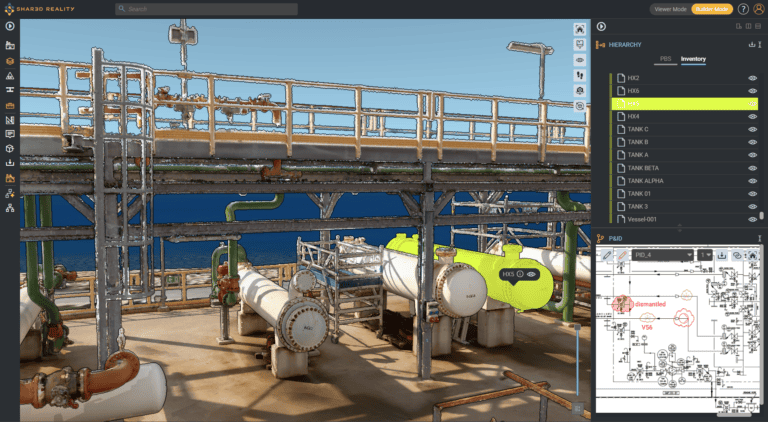

Whether you manage a single plant or multiple sites, whether your facilities are onshore or offshore, Shared Reality helps you build and maintain reality models within days. Major milestones in a plant’s lifecycle, such as handover from EPC to operator, change of ownership, revamping or decommissioning, provide an opportunity to implement a safer and more efficient way of working with your extended teams, regardless of the quality of your technical data.