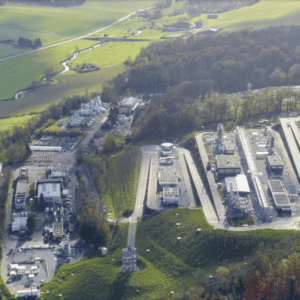

How can Storengy revamp sites more efficiently to comply with new regulations?

Challenge

The key challenge Storengy faced was the complexity of accessing technical information that was consistent with the actual field conditions. This disparity caused significant delays in project preparation and maintenance execution.

Solution

To address these challenges, Storengy teamed up with Samp, to deploy Shared Reality, that empowers all teams to prepare and execute their work with NO SURPRISE ON SITE.

By using the reality of the field as the single reliable source of truth, all work orders and projects are executed safely, efficiently and with no rework.

Results

Would you like to find out more?

"As Storengy does not have a 3D CAD model of its facilities, Shared Reality allowed us to quickly establish a functionally rich digital twin without a CAD model, and the 3D scans are a very accurate representation of the reality on the ground. Beyond that, we were able to aggregate our existing data sources, now accessible through Samp’s 3D streaming portal: document management system, data historian, risk database and maintenance management system. Shared Reality is a great solution that offers a 1D/2D/3D context to all our data, whether for operations, maintenance, engineering, remote expertise, training or communication."