How did SUEZ tackle operational challenges

in asset management?

Challenge

As a global leader in water and waste management, SUEZ operates complex water and wastewater treatment plants. However, poor asset knowledge and fragmented documentation made operations and upgrades challenging. Incomplete or outdated information slowed decision-making, increased risks, and made it difficult to optimize plant performance.

Solution

SUEZ needed a solution that would provide clear, accessible, and up-to-date asset information to their teams.

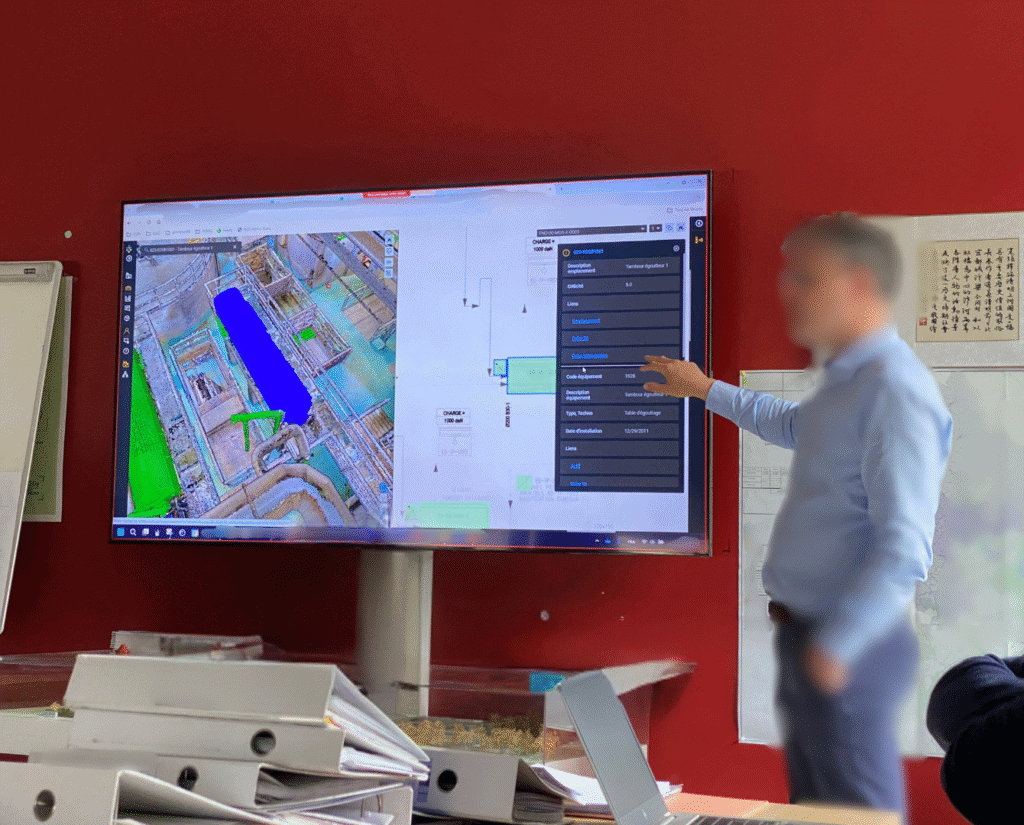

That’s why they team up with Samp. Through Shared Reality, they are transforming asset management with a dynamic digital twin environment that allows maintenance teams to access up-to-date site information, reduce downtime, and improve plant performance.

Results

Would you like to find out more?

"The perfect knowledge of the facilities we manage on behalf of local authorities is one of the success factors of our missions. The as-built digital twins of the operated sites, an up-to-date representation of the actual infrastructure, improve our technical performance and reduce our risks thanks to easier access to information, continuous data cleansing, optimized preparation of studies and worksAs a result, trust is improved between all stakeholders involved on site, from our operators to our subcontractors, without forgetting our customers, who benefit from greater transparency in our activity."