My Digital Buildings, a reality capture company pioneering dynamic scanning, and Samp, a deeptech company automating the generation of digital twins, have joined forces to accelerate the implementation of digital twins for industrial sites. Thanks to this partnership, My Digital Buildings will integrate Samp’s “Shared Reality” to its solutions catalog.

The origins of this partnership date back to 2020 when both companies first met at Station F, the world’s largest startup campus. Since then, they have partnered on major projects with major industrial companies like SUEZ and ENGIE. Recognition of each other’s expertise has led to the decision to deepen their collaboration. This partnership leverages speed, accuracy and responsiveness, to offer customers fast return on investment, and immediate value to end-users.

A synergy between 3D scans and Artificial Intelligence

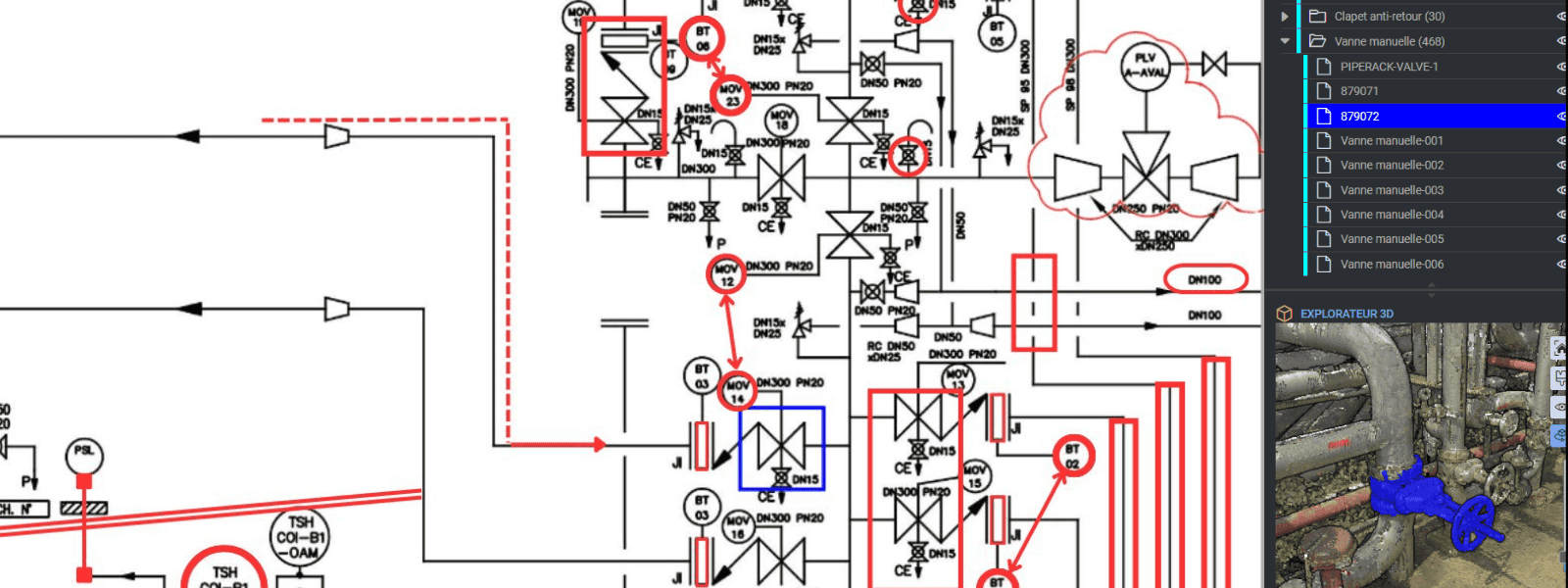

Samp’s innovative Shared Reality solution creates exact replicas of industrial sites in days, and links 3D reality capture with systems diagrams, thanks to proprietary Artificial Intelligence and 3D streaming technology.

Samp gives all teams instant access to a unique workspace, combining the view of the real site layout with the view of technical documents. This allows clients to maintain information consistency, in order to better execute costly and risky routines: P&ID revalidation, retrofit engineering, procurement, equipment isolation, commissioning, training or walkdowns.

Combined expertises to fast track digital twins

My Digital Buildings offers a unique 3D scanning service, structured to be efficient in every step of the process, particularly when it comes to manage multi-site industrial projects.

By relying on a network of agencies and 3D scanning workflows integrating dynamic scanners, MDB offers responsiveness, onsite speed and quick data delivery. The whole process of data capture is fastened, until the deployment on Samp’s solution, which is managed in a few days. This partnership represents and strengthens the commitment of both companies to accelerate the creation and implementation of digital twins.

Emeric Mourot, CEO of My Digital Buildings said: “We are delighted to partner up with Samp, with whom we share a common vision around the value of 3D point clouds.

Providing our clients with the best solutions to leverage their spatial data in specific use cases is key for us, and we know how much value a solution like Shared Reality can have.”

Laurent Bourgouin, CEO of Samp said: “I am thrilled by this partnership with My Digital Building, which is a catalyst for our commitment to deliver value at unparalleled speed to our customers. This is particularly meaningful at a time when climate adaptation is driving an accelerated transformation of their facilities.”

About My Digital Buildings

My Digital Buildings is specialized in the creation and exploitation of digital twins, and recognized for its ability to quickly and efficiently carry out large-scale 3D scanning operations. By relying on a capture network and rapid 3D scanning protocols, My Digital Buildings supports building actors in the production of the digital twin of their assets in multiple formats (point clouds; BIM / 3D models; 2D blueprints; virtual tours), delivered on a unique platform. https://www.mydigitalbuildings.com/

About Samp

Samp is a deeptech company that accelerates the transformation and decarbonization of industrial sites thanks to a digital twin of facilities, generated in just a few days directly from the field. Their web-based “Shared Reality” solution reconciles 3D scans of sites with technical documentation (inventories, drawings) that is often incomplete and rarely up to date. This patented solution, based on Artificial Intelligence and 3D streaming, brings simplicity and efficiency to industrial site modernization projects.