“Those who have adopted Shared Reality have slashed equipment inventory update time and cost by 80% and reduced ongoing OPEX by 15%”

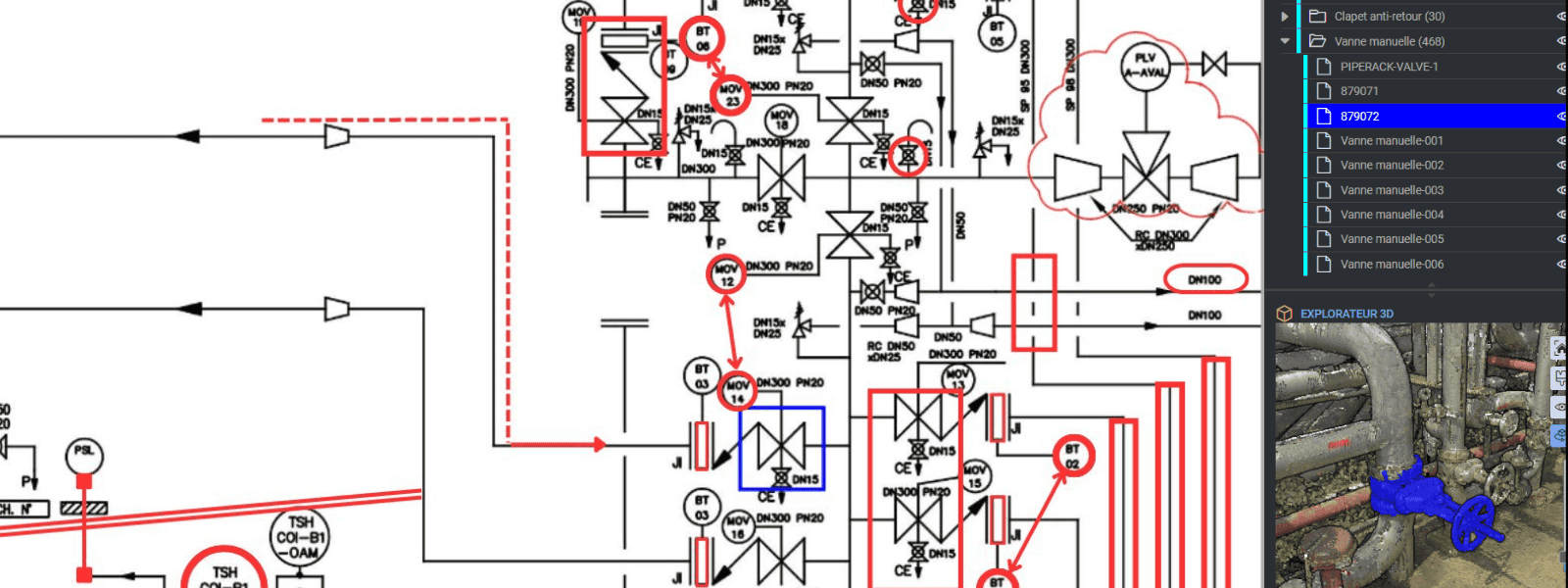

Laurent Bourgouin, CEO of Samp, is urging industrial operators to embrace Shared Reality – an AI-powered 3D digital workspace built to modernise outdated practices. Deployed in just a few days, Shared Reality generates a digital twin of industrial sites by aligning 3D scans with existing, often incomplete or outdated, technical documentation. This immersive, web-based solution brings together schematics, inventories, and engineering drawings into a single interactive model, accessible from anywhere. By enabling remote collaboration, faster decision-making, and dramatically safer working conditions, Shared Reality ensures data integrity across operations – marking a decisive shift toward a smarter, more agile, and connected industrial future.

“Too many teams are still relying on guesswork and outdated data to run critical infrastructure,” said Bourgouin. “Shared Reality changes that. It gives you a clear, current, and complete view of your site within days, straight from the field. If you’re not already using it, you’re falling behind.”

Samp’s Shared Reality solution has already demonstrated its value on hundreds of industrial sites across multiple sectors. It has cut the cost of engineering studies by nearly a third, halved on-site risk exposure and dangerous interventions, and reduced contract amendments by 60%. Customers have reported a five percent boost in plant uptime due to faster maintenance response, while others have slashed equipment inventory update time and cost by 80%.

The financial gains are equally impressive – averaging over €500,000 in CAPEX savings per site, per year, and a 15% reduction in ongoing OPEX.

“This is a wake-up call for the entire industry,” Bourgouin concluded. “Information chaos has been accepted for too long. Now, with Shared Reality, there really is no excuse.”

To facilitate this much needed awakening, Samp is even offering current customers of traditional 3D virtual visits a free switchover to Shared Reality, AI and 3D technology, turning outdated site data into an accurate model for faster, safer operations and decision-making.

For a greater understanding of the immediate benefits of Shared Reality, Samp is inviting industry leaders to see it in action.