LOD in BIM: An Overview

The term LOD, or Level of Definition, has dual meanings depending on whether the British or American perspective is considered.

- British Perspective (Level of Definition): Introduced by PAS 1192, it focuses on the level of detail in the architectural BIM model.

- American Perspective (Level of Development): This focuses on the development stage of each element in the BIM model, recognizing that detailed graphics do not always equate to a high development level.

LOD helps define the content of a BIM project at different development stages. It consists of two complementary aspects:

- LOG (Level of Geometry): The visual representation of the project.

- LOI (Level of Information): Data attached to BIM model objects, creating intelligent objects.

The American Institute of Architects (AIA) provides a standard LOD framework to represent the development stages of project elements, facilitating data exchange and communication among stakeholders. The LOD levels range from LOD 100 (symbolic representation) to LOD 500 (as-built representation).

In the UK, the Construction Industry Council (CIC) published a BIM protocol that defines responsibilities and outcomes at key process stages, aligning with the government’s BIM compliance strategy. The LOD stages in the UK range from LOD 1 (brief) to LOD 7 (in use).

The Evolution of LOD: Introducing LOIN

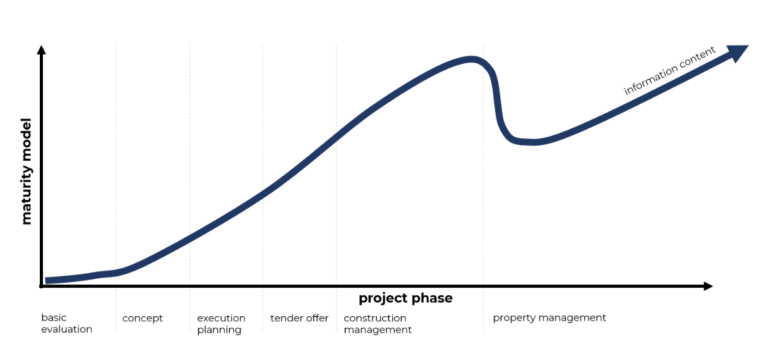

To address the issues of excessive and often unnecessary information sharing, ISO 19650-1 introduces the concept of the Level of Information Need (LOIN), which focuses on the specific information required at various design stages.

The name itself denotes a change of perspective: the emphasis is no longer on the characteristics of the object, but on the need for information that the object must contain in order to satisfy the needs of the professional at the precise moment of conception.

LOIN emphasizes the need for precise information depending on:

- Purpose (why?)

- Timing (when?)

- Stakeholders (who?)

- Organizational breakdown (what?)

The level of information need combines three types of information:

- Geometric: Shape, size, dimension, and position.

- Alphanumeric: Characters, numbers, symbols, etc.

- Documentation: Related documents.

LOD, LOIN, and 3D Reality Models

While LOD and LOIN frameworks were initially developed for 3D CAD models, they extend naturally to 3D Reality Models, which are semantic point clouds offering by default the highest possible visible geometric LOD thanks to reality capture. These models can be progressively linked with technical data as required by the Level of Information Needed.

With 3D Reality Models, the scan-to-BIM concept finally makes sense, without the scan-to-CAD-to-BIM detour!

3D Reality Models provide an incredibly detailed level of geometric (and colorimetric) representation that can be progressively enhanced by linking alphanumeric and documentary information as needed, to increase the level of information.

This incremental enrichment process aligns perfectly with the LOIN concept, ensuring that each model element contains the appropriate level of detail and information for specific stages and purposes within a project’s lifecycle.

Benefits of 3D Reality Models combined with LOIN

- Rapid Setup: The time required to create 3D Reality Models is much shorter than for 3D CAD models, generally 4 times faster at least ➡️ fast time-to-value

- Enhanced Visual Fidelity: 3D Reality Models provide “as-built” facilities representations with unmatched visual details ➡️ strong user adoption

- Improved Information Management: By applying the LOIN framework, only the necessary information is attached to equipment at each stage of the 3D Reality Model life cycle ➡️ progressive build-up & usage

- Efficient Update: From initial construction stages to maintenance and overhauls, 3D Reality Models are easier to update than 3D CAD models, which is essential to support the associated information update ➡️ single source of trust

Practical Applications for Industrial Owners and Operators

For industrial owners and operators, the integration of 3D Reality Models and LOIN offers significant practical benefits throughout the entire lifecycle of industrial facilities.

Design and Planning Phase

During the design and planning phase, 3D Reality Models provide a highly accurate geometric representation of existing conditions. This allows for precise planning and coordination, reducing the risk of errors and ensuring that all design decisions are based on reliable data.

- Enhanced Visualization: Industrial owners can visualize proposed changes in the context of the existing facility, improving decision-making and stakeholder communication.

- Detailed Analysis: The high level of geometric detail enables detailed analysis of spatial relationships, clash detection, and optimization of layouts for efficiency and safety.

Construction or Rehabilitation Phase

As the project moves into the construction, revamping or expansion phase, the combination of 3D Reality Models and LOIN ensures that all stakeholders have access and can contribute to trustworthy information with no delay.

- Accurate Fabrication and Installation: With detailed 3D Reality Model, fabricators and installers receive precise information about the components they need to manufacture or assemble, reducing errors and rework.

- Progress Tracking: 3D Reality Models can be rapidly updated to reflect construction progress, providing a visual and data-rich record that helps industrial owners monitor timelines and manage resources effectively.

- Test and Commissioning: Such detailed and up-to-date models better support testing and commissioning of systems and components than more abstract CAD models.

Operation and Maintenance Phase

During the operation and maintenance phase, the as-built 3D Reality Model becomes an invaluable tool for all facets of the site management.

- Comprehensive Asset Management: The detailed as-built model, enriched with LOIN connected to ERP/EAM/CMMS/EDMS/telemetry, allows for efficient tracking of assets, maintenance schedules, and performance metrics.

- Streamlined Maintenance: Maintenance teams can use the model to locate components quickly, prepare and execute isolation or lock-out tag-out procedures, reducing downtime and improving response times and safety.

- Lifecycle Management: Industrial owners can plan for future upgrades and retrofits with greater accuracy, using the detailed and up-to-date information provided by the 3D Reality Model.

Safety and Compliance

Maintaining safety and regulatory compliance is critical in industrial settings. The integration of 3D Reality Models and LOIN supports these goals efficiently in several ways:

- Risk Management: Detailed models help identify potential hazards and plan mitigations more effectively, enhancing overall safety.

- Regulatory Compliance: Accurate and detailed models ensure that all aspects of the facility meet regulatory standards, simplifying compliance audits and reporting.

- Testing, Inspection & Certification: The execution of TIC processes is simplified thanks to these up-to-date models, which provide detailed visual information (corrosion, cracks, buckling …).

Cost Management

Effective cost management is a priority for industrial owners and operators. The use of 3D Reality Models with the right LOIN contributes to cost savings through:

- Reduced Rework: Accurate and detailed information minimizes errors during design and construction, reducing costly rework.

- Optimized Procurement: Enriched procurement context, supported by detailed models, optimizes tendering transparency and costs while reducing variation orders.

- Asset Investment Planning: Access to precise and relevant asset information allows for better budgeting and financial planning throughout the facility’s lifecycle.

Wrapping it up

By leveraging the combined power of 3D Reality Models and LOIN, industrial owners and operators can achieve greater efficiency, accuracy, and cost-effectiveness in managing their facilities.

This streamlined BIM technique provides a faster and simpler approach to industrial assets management compared with traditional CAD-based BIM, ensuring optimal performance and long-term value.

It is made possible by the widespread availability of 3D reality capture, and Samp’s unique combination of 3D AI and 3D streaming infrastructure.