Teréga announces the industrial commissioning of the TwiX application (Twin for eXploration). Based on Samp’s cloud solution, this innovative digital twin aims to assist Teréga teams and our subcontractors in modernization projects and in the daily operation of our industrial facilities.

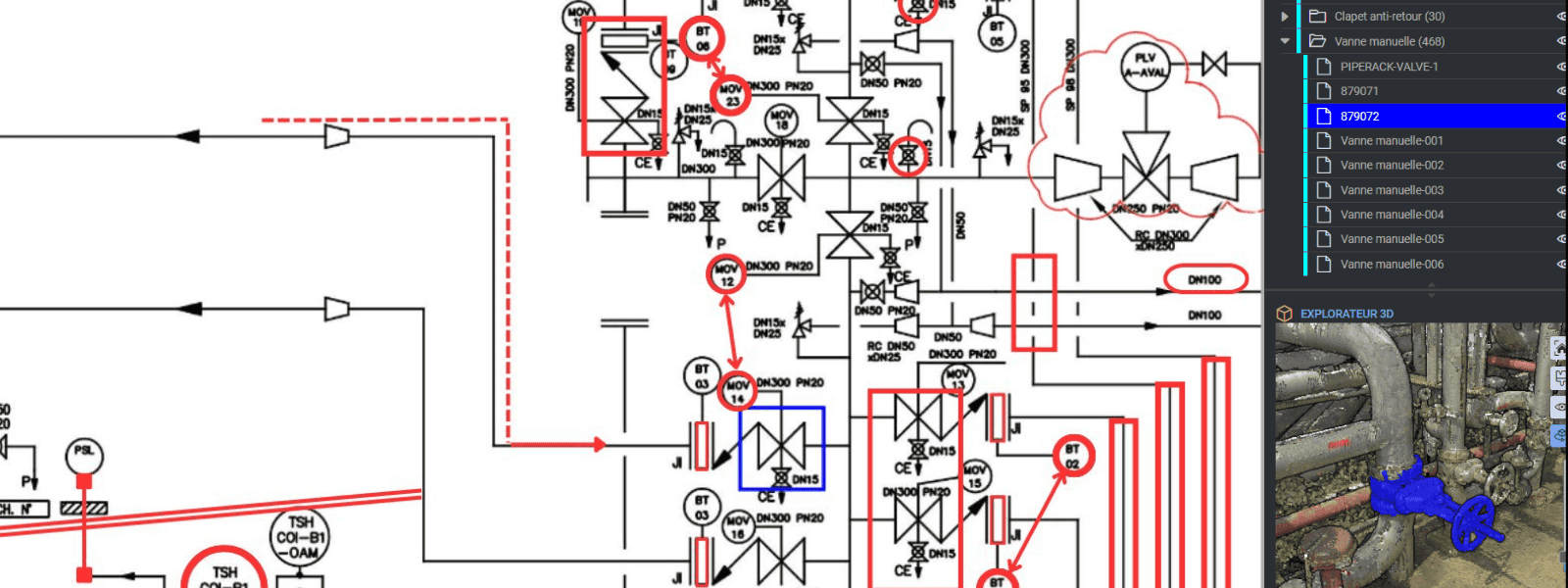

Samp makes it possible to quickly visualize accurate 3D digital twins of Teréga’s industrial facilities by combining several data sources. This guarantees all teams immediate access to a 360° view of our industrial assets.

Our storage sites, based in Lussagnet and Izaute, have been completely scanned, over an area of around 80,000 sqm. This scanning campaign accurately captured a set of 12,000 tagged equipment and lines of piping, which were associated with the corresponding technical diagrams with the help of Samp’s artificial intelligence.

Thanks to this application, we are able to deliver a realistic visualization of our sites, simultaneously with a system view, and give a better common understanding of our processes, flows and technical interactions.

During the preparation and execution of modernization projects or for operation and maintenance routines, operational and engineering teams, as well as our subcontractors, can make more informed decisions, better anticipate potential problems and optimize field operations, which results in significant savings in time and money.

The deployment of the TwiX application marks a significant step forward in Teréga’s digital transformation, demonstrating its commitment to technological innovation. Thanks to this solution based on digital twins, Teréga is positioned as a pioneer in the adaptation of industrial facilities, while guaranteeing the continuous improvement of their safety and reliability.