Is traditional BIM still fit for purpose in the water industry?

For more than a decade, Building Information Modelling (BIM) has promised better data, better decisions, and improved performance. Yet for many water and utilities operators, traditional, design-centric BIM is failing to support what matters most: day-to-day operations and maintenance.

In a recent article published by Water Industry Journal, Razvan Gorcea, Water & Utilities Director at Samp, explores why BIM has struggled to deliver long-term operational value in critical infrastructure sectors such as water and wastewater.

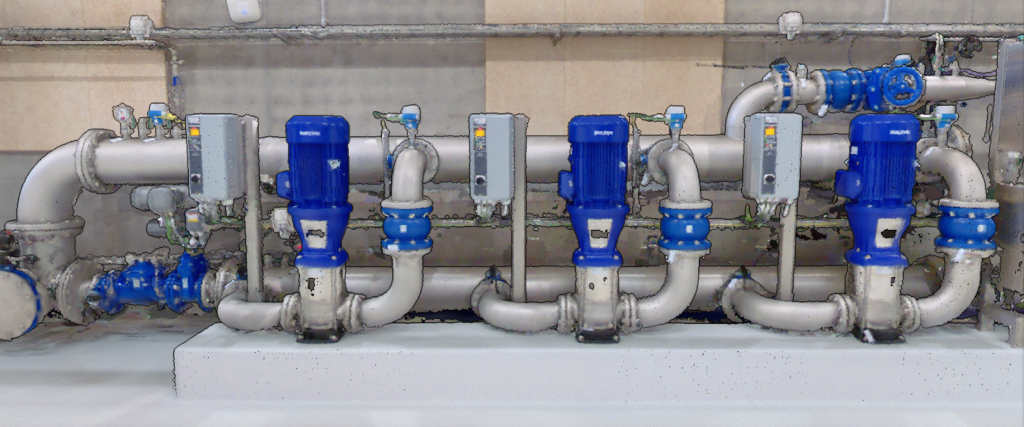

Despite major advances in 3D scanning and reality capture, much of the industry response has focused on Scan-to-BIM – creating increasingly complex and heavy models that are costly to maintain and rarely used by operational teams. The result is a growing gap between documented assets and site reality, increasing operational risk, delays, and maintenance costs.

Water operators need simple, reliable, and up-to-date information they can trust – without relying on specialised software or expert modelling skills. This is where a new approach, Scan-to-Value, is gaining traction.

By working directly from reality capture and using AI to structure data for operational use, Scan-to-Value enables lightweight, operational-first digital twins. These solutions are built for technicians, asset managers, and contractors – providing a shared, accessible view of the real facility rather than static design artefacts.

Traditional BIM still plays an important role in design and construction. However, as the sector faces increasing pressure from ageing infrastructure, climate change, and regulatory scrutiny, the future of digital transformation in water lies in operational digital twins – such as Samp‘s Shared Reality – that prioritise clarity, trust, and usability.

This article was originally published by the Water Industry Journal.