Across Europe and around the world, chemical operations run on precision. Every valve position, every line routing, and every piece of safety equipment must be exactly as documented, because in this industry, the smallest mismatch can have costly or even dangerous consequences.

Yet, there’s a silent risk that quietly grows inside many facilities: the slow drift between what’s on paper and what’s on site. It doesn’t make headlines until something goes wrong, but by then, it’s already caused delays, unexpected costs, last-minute operational changes, or worse, safety incidents.

This problem isn’t unique to one plant, one company, or even one country. It’s a shared challenge across the sector. The good news? With the right approach, this risk is entirely preventable.

How Data Drift Happens, Why It’s Inevitable Without the Right Tools

A facility is never truly “finished.” Equipment gets swapped, new lines are routed, isolation points are added, and small modifications occur constantly. These changes are often urgent or part of very large multi-company revamping projects, done for safety, production or operation reasons, and documentation updates don’t always keep pace.

Over time, the differences between the “official” version of the plant and its real state accumulate. Engineers might be working from outdated P&IDs. Maintenance teams might rely on memory instead of verified diagrams. Project teams might start with inaccurate layouts, only to discover the truth mid-turnaround.

Add to this the fact that critical data is often spread across multiple systems – CAD drawings, scanned P&IDs, CMMS, EAM – each updated by different people at different times, and the drift accelerates.

The Real-World Impact of Mismatched Data

In a safety-critical sector like chemicals, even minor discrepancies can have disproportionate effects:

- Safety risks: Work permits issued based on outdated diagrams can lead to incidents.

- Cost overruns: Rework during shutdowns when the plan doesn’t match reality.

- Project delays: Teams having to stop and verify conditions on-site before continuing.

- Lost productivity: Hours spent reconciling mismatches instead of executing work.

In our experience and based on industry analysis, where up to half of turnaround delays are linked to poor communication and outdated data, it is realistic to estimate that over 30% of delays stem from outdated documentation.

A Living View of the Facility

Many companies have invested in “digital twins” – virtual replicas of their facilities. But without continuous updates, a digital twin quickly becomes just another outdated file.

What plants truly need is a living representation of their site, kept in sync with reality, and accessible to everyone from control room operators to external contractors.

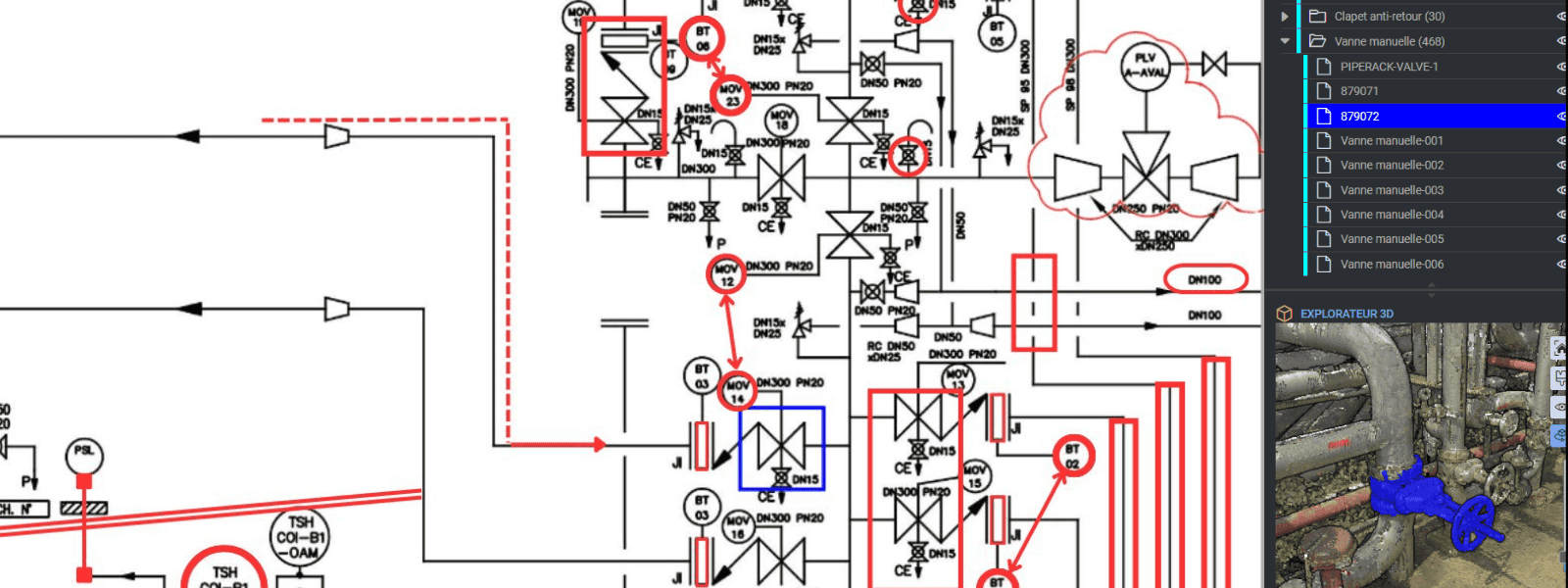

This is where Shared Reality comes in. It’s a visual, intuitive workspace that can unite 3D scans, process diagrams, and asset databases in one place, easily updated to match the real world. The goal is simple: one source of truth that everyone can trust.

It is important to note that Shared Reality doesn’t replace existing tools like CMMS or predictive maintenance systems, it connects to them, providing a verified, visual foundation trust by all teams across all systems.

Practical Impact for Chemical Operations

In chemical plants, where processes are complex and safety margins tight, combining 3D reality models with process diagrams can make certain hazards easier to detect before anyone steps onto the site. Tight clearances, risky equipment isolation, or confined spaces can be identified virtually, allowing work to be planned more efficiently and more safely.

For turnaround projects, this means fewer on-site surprises and shorter preparation times. For contractor onboarding, it means faster familiarization with site layouts. As shared reality has a very intuitive user interface, and integrates with existing CMMS, EAM, and document systems, adoption is quick – weeks instead of years.

The Human Impact – Teams That See the Same Reality

Beyond the technical efficiencies, there’s a cultural shift when everyone in a facility works from the same, verified view. Disputes over “which version is correct” disappear. Trust grows between departments. Decisions are made faster because everyone is looking at the same picture.

When the physical and digital match, communication improves, safety strengthens, and operational resilience grows.

Building Resilience in an Evolving Industry

The chemical industry faces increasing pressure from EU safety regulations, environmental compliance requirements, and efficiency demands. Keeping plant data fully aligned isn’t just about avoiding problems, it’s about enabling the future.

Accurate, shared data makes it easier to implement sustainability upgrades, adopt automation, and integrate advanced systems. It turns every improvement project from a risky leap into a calculated step.