In a recent interview, Thomas Grand, COO of Samp, shared his perspective on one of the water sector’s most pressing challenges: how to modernize ageing infrastructure in the face of climate disruption. As climate change accelerates and infrastructure ages, operators in the water sector are under growing pressure to adapt. Thomas explores how digital tools, especially AI and digital twins, are becoming essential to managing assets more intelligently, improving safety, resilience, and long-term sustainability.

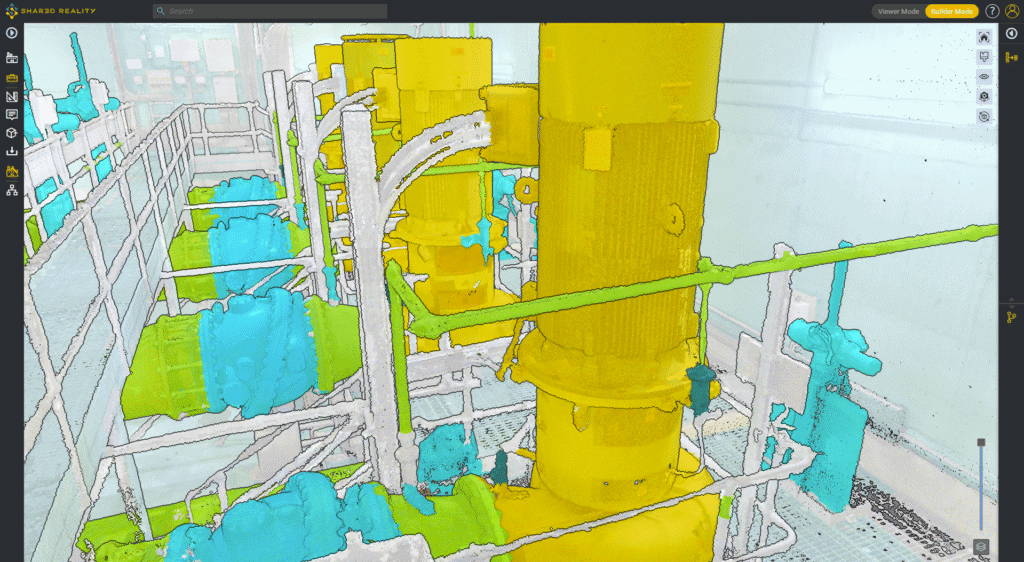

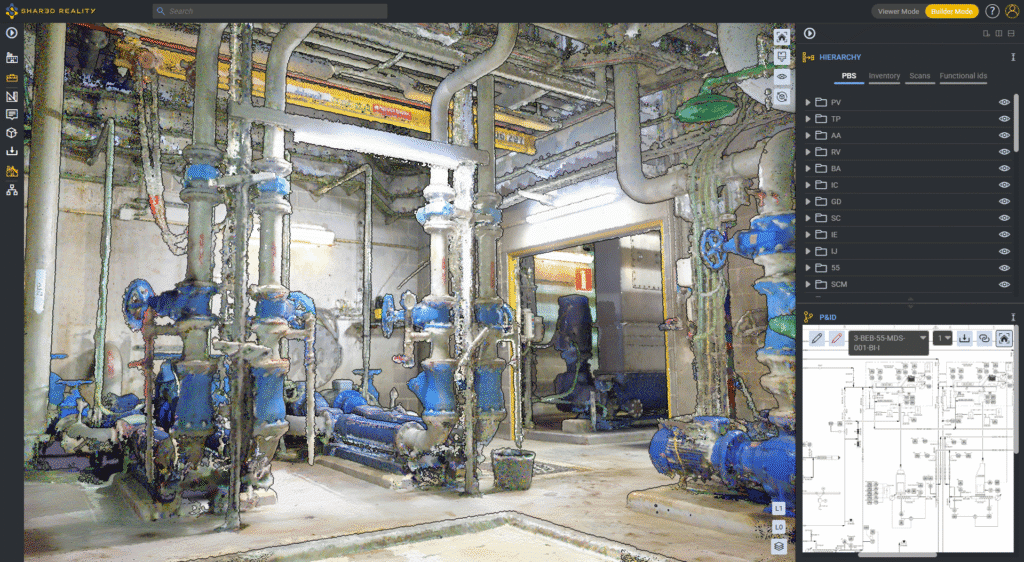

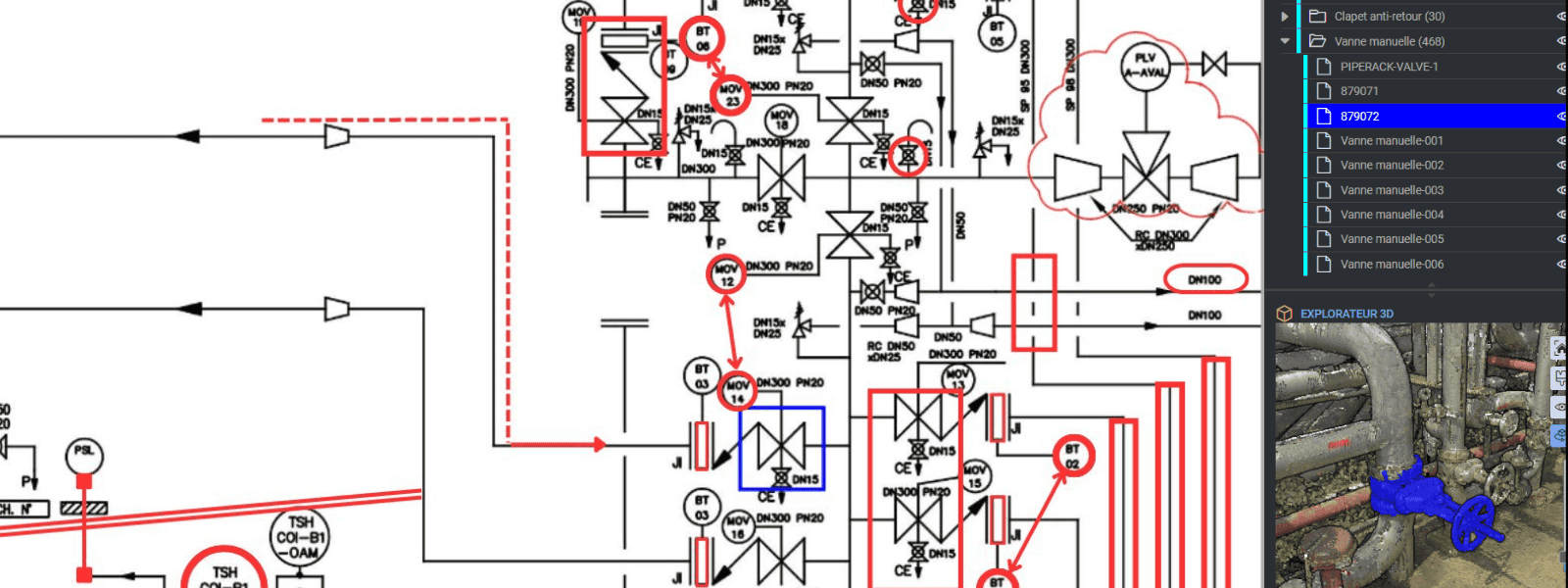

He explains how one of the biggest barriers today is the disconnect between physical infrastructure and technical documentation. Many facilities operate with outdated or incomplete data, making it difficult to plan, maintain, or upgrade assets effectively. Shared Reality, Samp’s collaborative digital workspace, addresses this gap by combining 3D scans of real-world sites with AI-driven recognition and data linking. It helps match physical assets to their digital counterparts, creating a continuously updated and reliable view of actual infrastructure conditions. This shared environment ensures that all stakeholders – from engineers to subcontractors – can work from the same accurate, up-to-date information, improving collaboration and operational efficiency across the board.

By working within this intuitive 3D environment, teams can align on current site conditions, streamline operations, and make better-informed decisions across projects. This shared view is key to future-proofing water infrastructure, ensuring that investments lead to more efficient, cost-effective, and climate-resilient outcomes. As Thomas makes clear, the adoption of AI-driven solutions like Shared Reality marks a turning point in how the water sector can meet the challenges of today and those still to come.

For the full interview published on June 24, 2025, visit the Water Industry Journal site. The article has also been published in the e-magazine here (page 42).