SUEZ and SAMP sign a partnership to improve the resilience of water infrastructure through digital twins

During the POLLUTEC show, SUEZ, leader in circular solutions in water and waste, and SAMP, a deeptech company accelerating the transformation of industrial sites with digital twins, announce the signature of an agreement to develop and deploy a digitalization solution for water and wastewater production facilities operated by the group in France.

A partnership to accelerate digital twin deployment

Digital Twin solutions – virtual models of real assets – enable water and wastewater utility managers to gain a better understanding of their facilities to optimize maintenance and operations. They provide a decision-making tool to reinforce the ability to adapt to the increasing number and intensity of extreme weather events, which jeopardize the operation of the sites.

Initiated in 2020, the collaboration between SAMP and SUEZ has enabled an initial pilot phase to be carried out on several dozen drinking water and wastewater plants operated by the SUEZ Group. The new agreement will allow the Group to extend the deployment of this technology to other water and wastewater facilities operated in France, as well as to assess the potential for development in other markets. SUEZ is strengthening its infrastructure performance and asset management offering by adding new capabilities to its digital twin solutions.

3D reality capture and artificial intelligence for operational performance

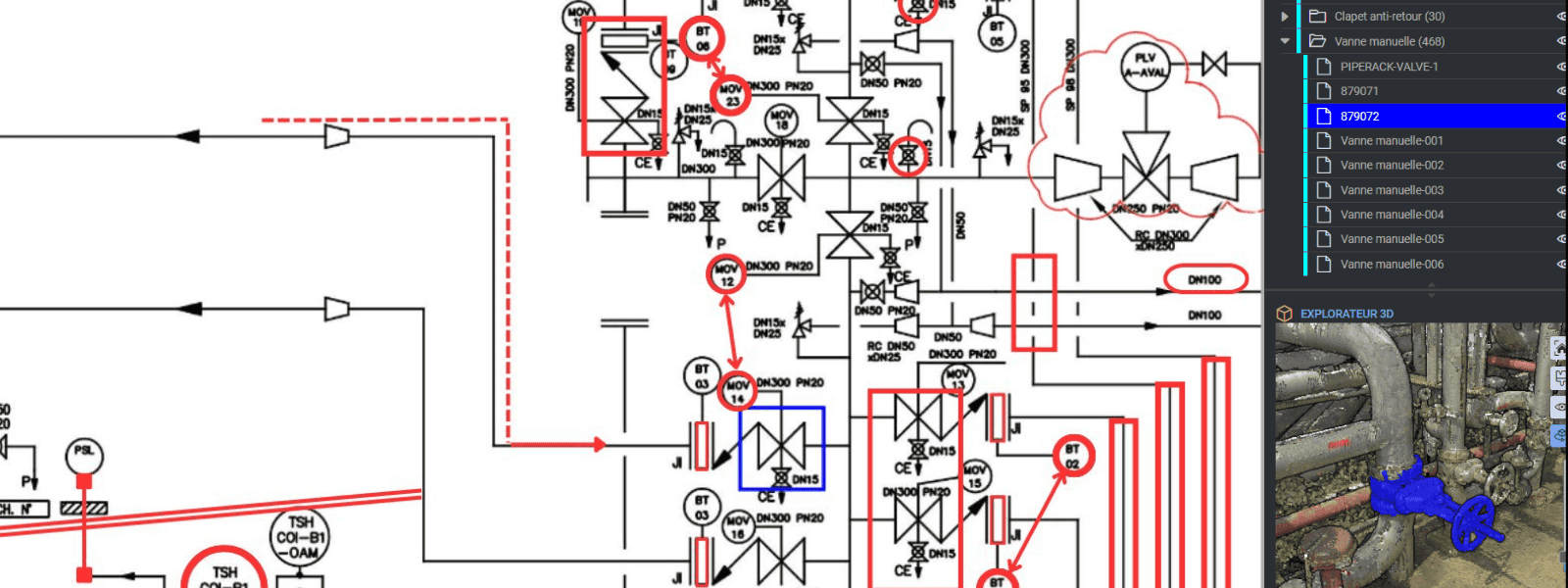

In just a few days, SAMP‘s “Shared Reality” solution can create digital twins of facilities, exact copies of the sites. Relying on artificial intelligence and 3D technology, it links technical site information (inventories, drawings) with their 3D reality capture, enabling the digital twins to evolve continuously in line with changes in the field. Operations teams access reliable, contextualized data, and can work virtually on the plants before acting in the field. This digitized environment improves working conditions and safety on site, and offers the opportunity to carry out optimized maintenance and refurbishment plans. It reduces the risk of errors and breakdowns in the day-to-day management of water and wastewater services, thus helping to preserve assets and the environment.

Arnaud Bazire, CEO of SUEZ Eau France, states: “Preserving water resources and protecting the environment are more than ever at the heart of our customers’ and citizens’ concerns. By strengthening our offering in digital twins, we are pursuing our commitment to supporting our customers in the efficient and sustainable management of their infrastructures, while enabling them to create value over the entire lifecycle of their infrastructure.”

Laurent Bourgouin, President of Samp, declares: “Our ‘Shared Reality’ solution is the catalyst that allows industrial sites to become more reliable and accelerate their transformation towards more sustainable production. This collaboration with SUEZ confirms our shared vision of the fundamental need for disruptive digital approaches to meet the industry’s huge challenges in terms of safety, resilience and the environment.”

About SUEZ

Faced with growing environmental challenges, SUEZ has been delivering essential services that protect and improve our quality of life for more than 160 years. SUEZ provides its customers with innovative and resilient solutions for water and waste services. With 40,000 employees across 40 countries, the Group works with customers to create value over the full lifecycle of their assets and services, and to drive their low carbon transition. In 2022, SUEZ provided drinking water for 68 million people worldwide and sanitation services for more than 37 million people. The Group generated 3.7 TWh of energy from waste and wastewater, and avoided 4 million tons of CO2 emissions. In 2022, SUEZ has generated revenues of 8.8 billion euros*. For more information: www.suez.com/ Twitter @suez

*restated on a 12-month basis.

About SAMP

Samp is a deeptech company that accelerates the transformation and decarbonization of industrial sites thanks to a digital twin of facilities, generated in just a few days directly from the field. Their web-based “Shared Reality” solution reconciles 3D scans of sites with technical documentation (inventories, drawings) that is often incomplete and rarely up to date. This patented solution, based on Artificial Intelligence and 3D streaming, brings simplicity and efficiency to industrial site modernization projects.