After attending BIM World this week, we wanted to share some thoughts about the value and limitation of using 3D CAD or 3D BIM models to manage facilities in operation. All the people we talked to during the trade show agreed.

3D CAD and 3D BIM models are useful for new build projects, or to modify existing facilities, whether they are buildings, infrastructure, or industrial sites.

But is this a realistic option for managing operating sites, or is this approach “overkill”? 3D point clouds captured directly onsite by field workers can be a more reliable and affordable option to build as-built models and keep them up to date, here is why.

Acting on the wrong system in operation due to ambiguous information is a common problem. Failure to update technical information after a change is unfortunately the norm, and leads to an ever-widening gap between the as-documented state of a facility and its real as-built state.

In recent years, a new trend has emerged to use 3D CAD or 3D BIM models beyond the project stage: during operations. At BIM World, many exhibitors showcased 3D CAD or 3D BIM models to display information made accessible to everyone in an intuitive manner.

If a picture is worth a thousand words, 3D surely is worth even more. It is an extremely effective way to convey information. This should not be a surprise, as many studies point to the power of visual perception:

- 90% of the information processed by the brain is visual.

- It takes only 13 milliseconds for the human brain to process an image.

- The human brain processes images 60,000 times faster than text.

- When people hear information, they’re likely to remember only 10% of that information 3 days later. If a relevant image is paired with that information, people retained 65% of the information 3 days later.

Positioning 3D as a medium is therefore seen as the cure to poor access to information by operating personnel, and especially for the lack of feedback maintenance personnel provides about its field activity (who likes filling out paper or digital forms?).

So 3D is definitely a good idea to help maintenance or inspection staff be better prepared before they act, and to encourage them to close the information loop for their own benefit.

But is 3D CAD or 3D BIM the right answer? Maybe not, because these 3D models are not updated either! The loop between the field personnel and the 3D model is long and costly. See for yourself:

So how do you harness the visual cognitive power of the brain, without suffering a long chain of command between fieldwork and updating the 3D model?

Simply by using an object-oriented 3D point cloud, captured from the reality of the field, rather than a theoretical 3D CAD or 3D BIM model, which is almost immediately outdated.

“an object-oriented 3D point cloud”

Static & mobile lidar scanners as well as photogrammetry software are now commodities. Capturing a 3D point cloud is fast, reliable, and affordable. The automatic segmentation of point clouds into objects capable of carrying information at equipment level is at the heart of Samp’s patented technology.

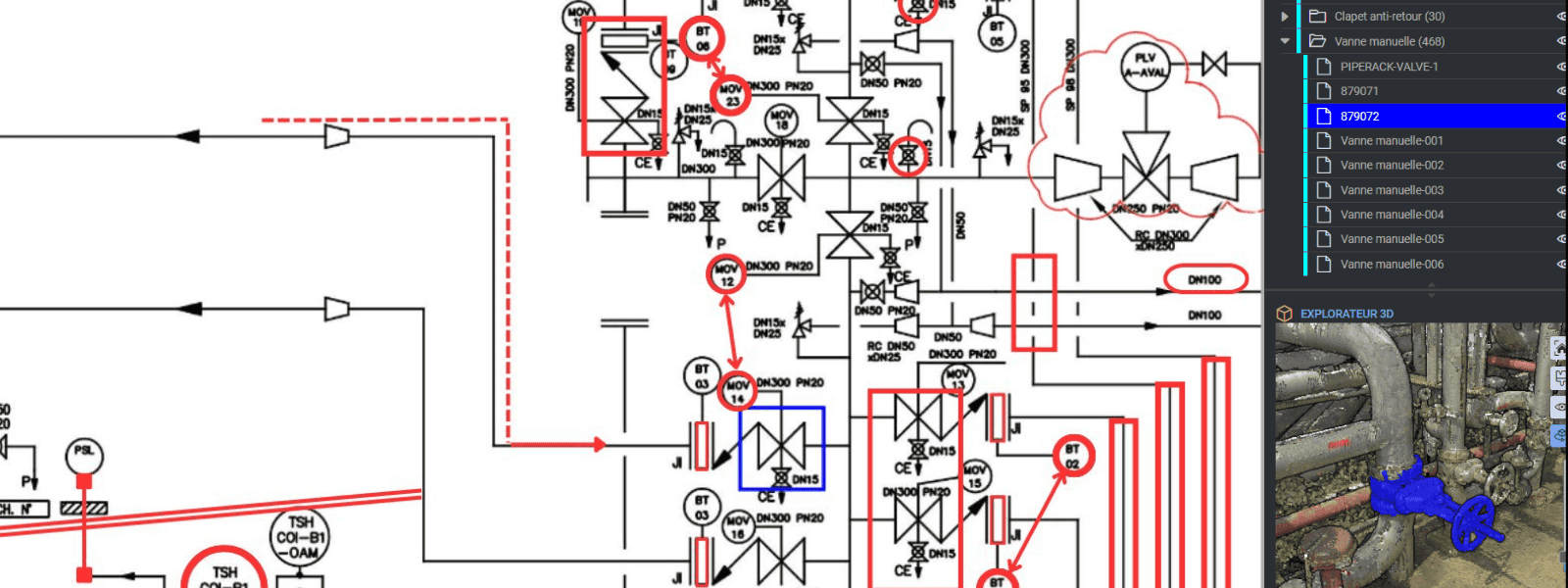

Objects automatically created by Samp’s AI can easily be hidden, grouped, labeled to carry an equipment ID or area name, and then become searchable by anyone using the 3D streaming portal. Samp’s scientific work further empowers users by helping them map these as-built 3D objects to their as-documented P&ID tags.

This opens the door to using this 3D captured on the field to keep the model up to date. Without remodeling, neither manual nor automatic. It is possible, it is simple, it is reliable. The idea is to move away from the “scan-to-BIM” concept and to focus on “scan-to-value”.

“moving away from scan-to-BIM”

As field workers now use digital devices on site, they can take pictures of the workface in seconds when the job is completed. Once uploaded, these pictures are then automatically turned into a local point cloud, which will replace the previous equipment in the as-built plant 3D point cloud model.

In other words, Samp allows to replace a theoretical and “fast expiring” 3D CAD or 3D BIM model, with a recent reliable 3D point cloud captured directly from the field. It is kept “always fresh” thanks to a super simple and very short self-service update loop, from the field worker to the overall site model.

“self-service”

As a side benefit, colored point clouds offer an excellent visualization and navigation user experience. Their main advantage is that they make panoramic photos or meshed models unnecessary, which avoids hosting redundant – and often inconsistent – representations of the facility.

Therefore, however rich & precise 3D CAD or 3D BIM is, it is probably “overkill” for real-life use cases at operating sites. A simpler and more effective approach is to use a short loop where inspection or maintenance teams easily update by themselves the 3D they use daily.

Only this way users will trust that the 3D remains faithful to as-built reality. Day after day.

Do you want to continue the conversation and take action? Get in touch with Samp!