Industrial digital twins are a powerful approach to better project planning, execution, and maintenance through virtual representations of physical assets.

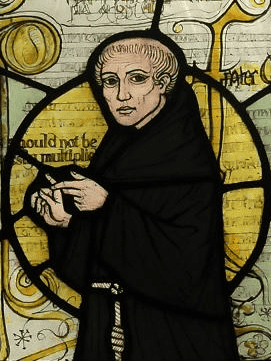

Ockham’s principle, also known as the principle of parsimony or Ockam’s razor, is the idea that the simplest explanation or solution is usually the best.

It is attributed to William of Ockham, a 14th-century English philosopher and theologian.

“Plurality is not to be posited without necessity” (Wikipedia)

Limitations of Digital Twins

Digital twin technology, when applied to the continuous process industry, are often faced with limitations such as complexity in data management, difficulty in keeping the digital twin up to date with its physical counterpart, as well as high costs and long lead times associated with implementation.

However, Ockham’s principle can be used to address these limitations by simplifying the input dataset needed, minimizing architecture design, reducing implementation costs, and enabling continuous update of the twin by empowered field workers and engineers.

Another bad day with a digital twin (Wikipedia)

Benefits of Ockham’s Principle

When applying Ockham’s principle to digital twins, minimal input data such as 3D from reality capture and 2D from Piping & Instrumentation Diagrams can be used to represent the as-built (real) and as-documented (assumed) states of facilities and networks.

Linking these two representations at equipment level can be used to identify discrepancies, while facilitating work between field personnel and engineers. The unique tag identifier of each equipment allows for querying existing systems of records from 3D or P&ID, without the need for heavy migration.

Furthermore, minimal input data allows for an easier continuous update, which is crucial for the safety and reliability of facilities and networks in the continuous process industry.

William of Ockham depicted on a stained glass window at a church in Surrey (Wikipedia)

Bottom Line

Applying Ockham’s principle to digital twins is what Samp does. The team’s unique industrial and scientific expertise means that the burden of dealing with sparse and imperfect input data lies with the AI, not with the users, who can exploit their existing technical data.

Industries such as water, natural gas, and district heating should consider applying Ockham’s principle to their digital twin implementations to reduce risk, ensure adoption, and achieve faster, actionable results faster when upgrading or maintaining aging industrial plants or networks.

Samp web solution in action. Under a week at your site!

More on Ockham: https://plato.stanford.edu/entries/ockham/