Shared Reality disrupted the way industrial operators connect equipment within a 3D scans to their technical data and symbols in... read more

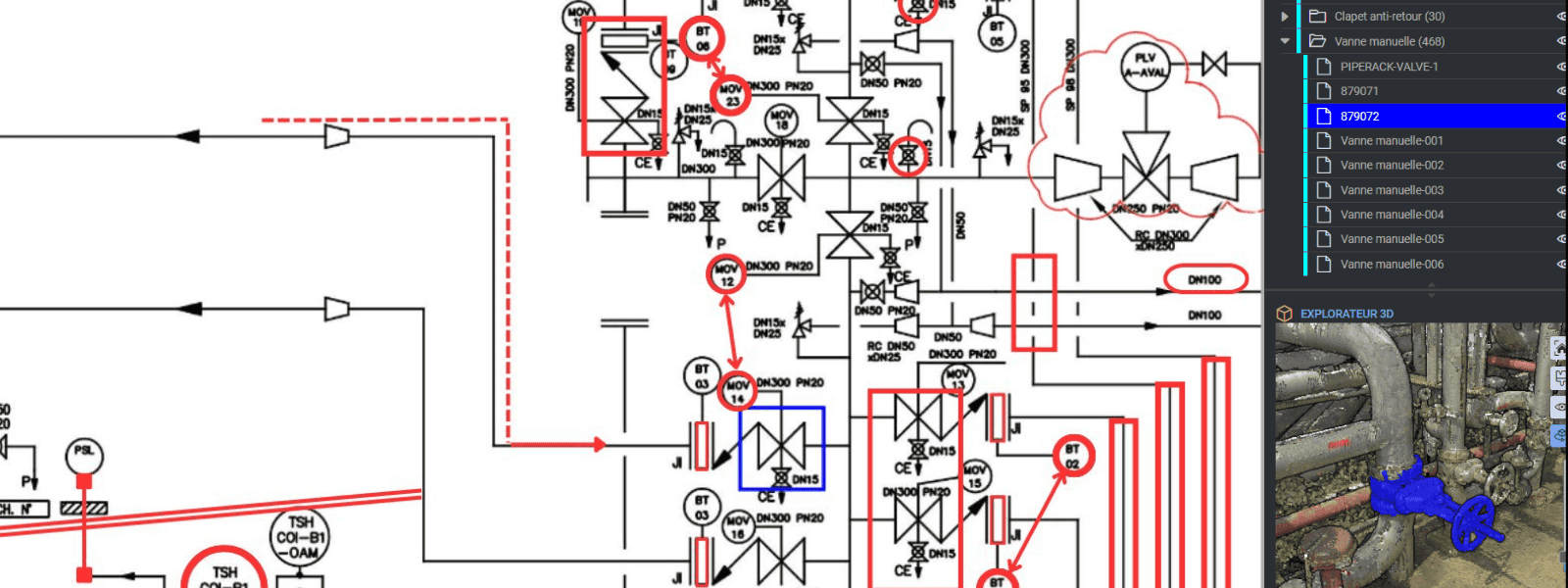

Shared Reality disrupted the way industrial operators connect equipment within a 3D scans to their technical data and symbols in a P&ID. This new capability helps you annotate discrepancies between your documentation and the actual field conditions effortlessly. Take your team's redlining skills to the next level!

In this webinar, we explore the latest capabilities of the Shared Reality workspace, now enriched with interactive 360° panoramic photos.... read more

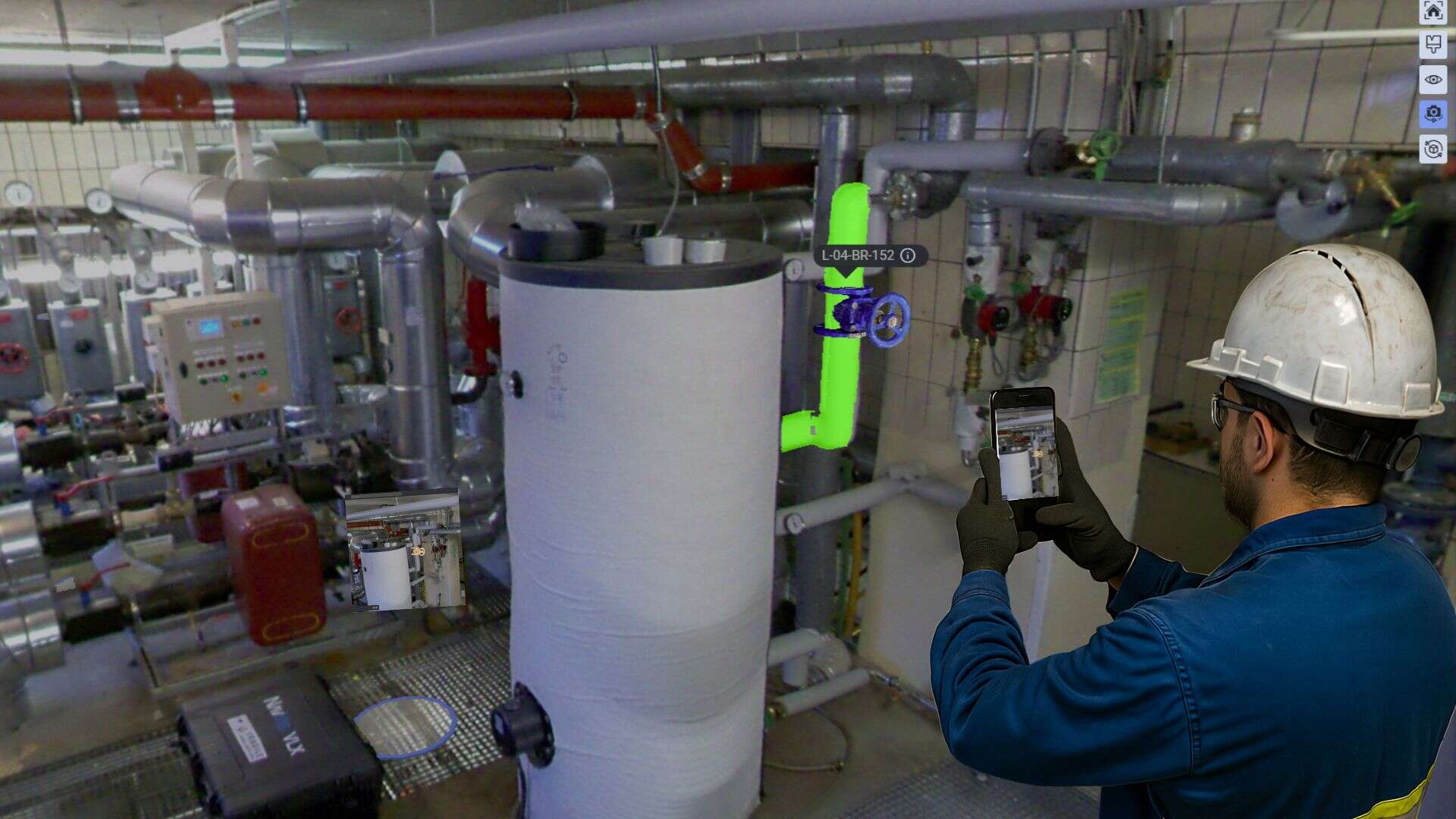

In this webinar, we explore the latest capabilities of the Shared Reality workspace, now enriched with interactive 360° panoramic photos. Whether you’re a casual user exploring sites virtually or an experienced engineer working with complex 3D digital twins, this new capability makes your reality capture data more accessible, powerful, and insightful than ever.

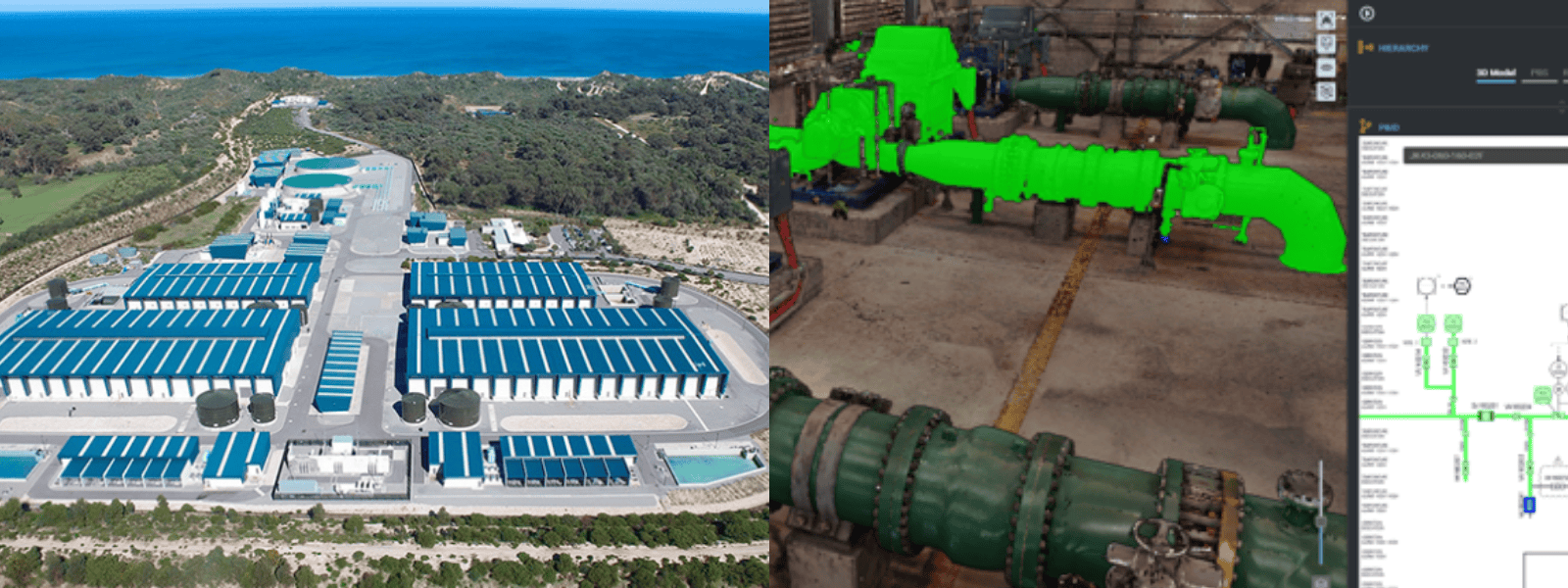

Après un premier webinaire sur la transmission du patrimoine, nous poursuivons avec un focus sur la vie d’une usine :... read more

Après un premier webinaire sur la transmission du patrimoine, nous poursuivons avec un focus sur la vie d’une usine : interventions du quotidien, rénovations lourdes, enjeux et bénéfices pour tous les acteurs.

Ce nouvel épisode réunit Razvan Gorcea (Samp) et Florian Pouilly (AMO BIM – Épigram), avec les retours d’expérience de SUEZ Eau France et d’un expert BIM côté conception et travaux.

Ce nouvel épisode réunit Razvan Gorcea (Samp) et Florian Pouilly (AMO BIM – Épigram), avec les retours d’expérience de SUEZ Eau France et d’un expert BIM côté conception et travaux.

La transmission des données d’exploitation est un moment clé : lorsqu’un site change d’exploitant ou de gouvernance, tout repose sur... read more

La transmission des données d’exploitation est un moment clé : lorsqu’un site change d’exploitant ou de gouvernance, tout repose sur la capacité à partager la connaissance et à structurer l’existant.

Avec Shared Reality, Samp apporte une approche innovante pour sécuriser cette étape, renforcer la continuité et créer une base solide pour les exploitants et les collectivités.

Avec Shared Reality, Samp apporte une approche innovante pour sécuriser cette étape, renforcer la continuité et créer une base solide pour les exploitants et les collectivités.

With 3D BI, you can:

Access metadata and analytics directly in 3D Reality Models

Visualize entire facilities at... read more

Access metadata and analytics directly in 3D Reality Models

Visualize entire facilities at... read more

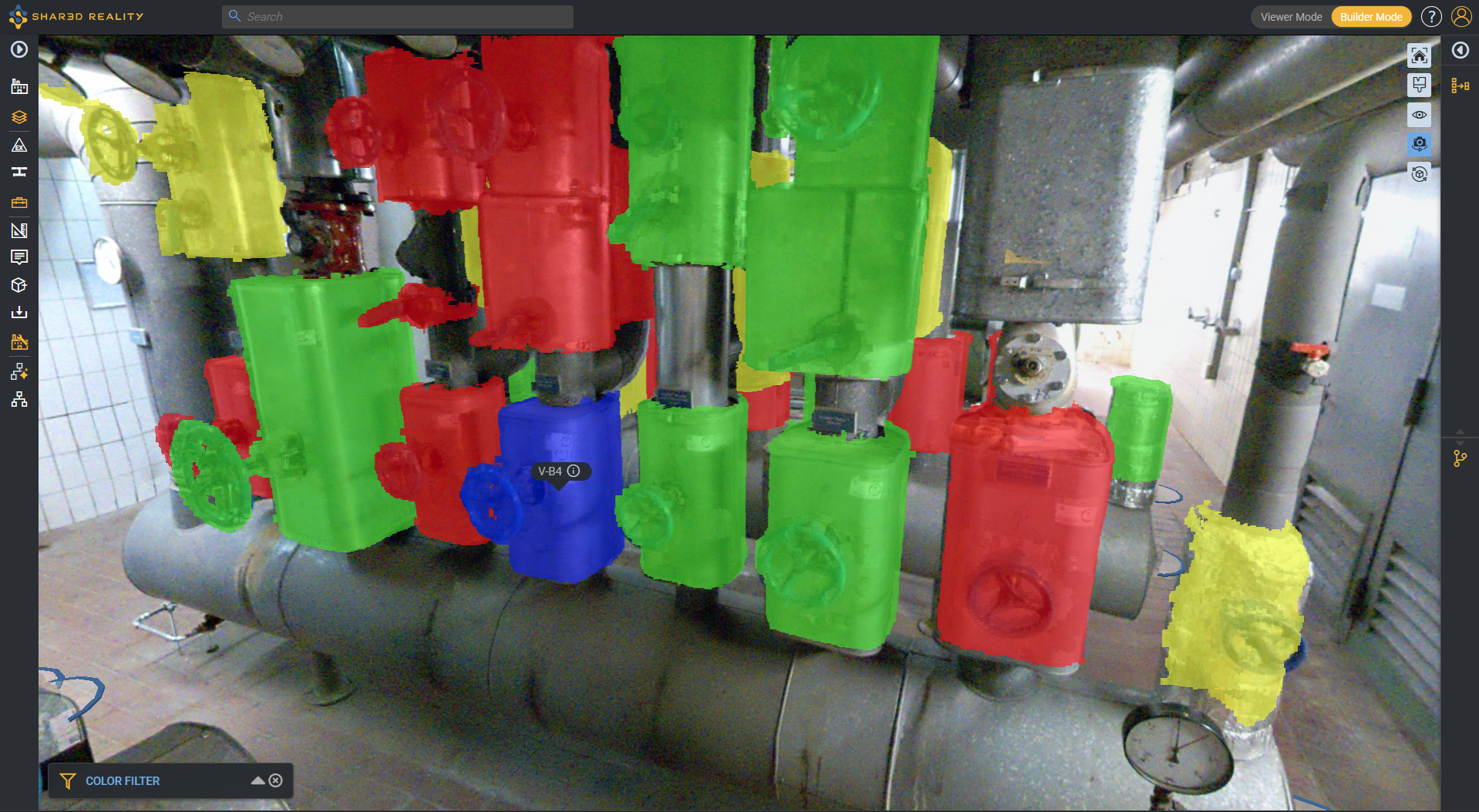

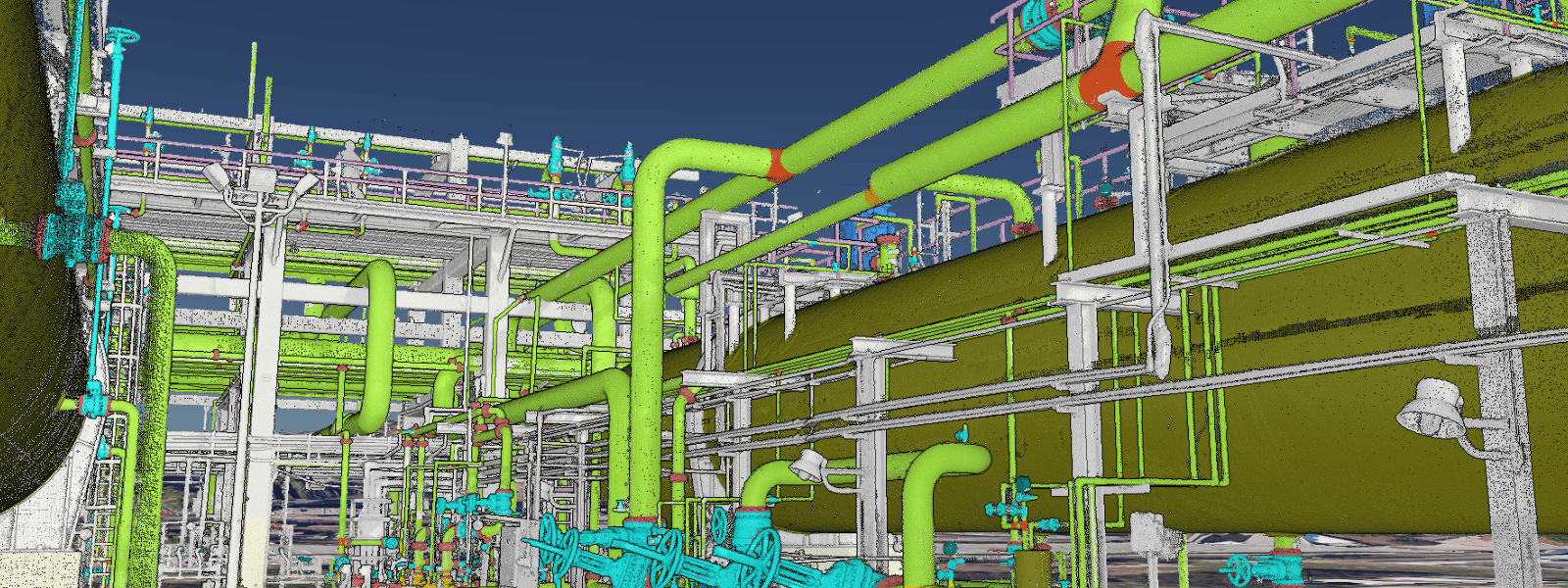

With 3D BI, you can:

Access metadata and analytics directly in 3D Reality Models

Visualize entire facilities at scale, filter and colorize any view

Improve asset management, maintenance, and engineering workflows

Access metadata and analytics directly in 3D Reality Models

Visualize entire facilities at scale, filter and colorize any view

Improve asset management, maintenance, and engineering workflows

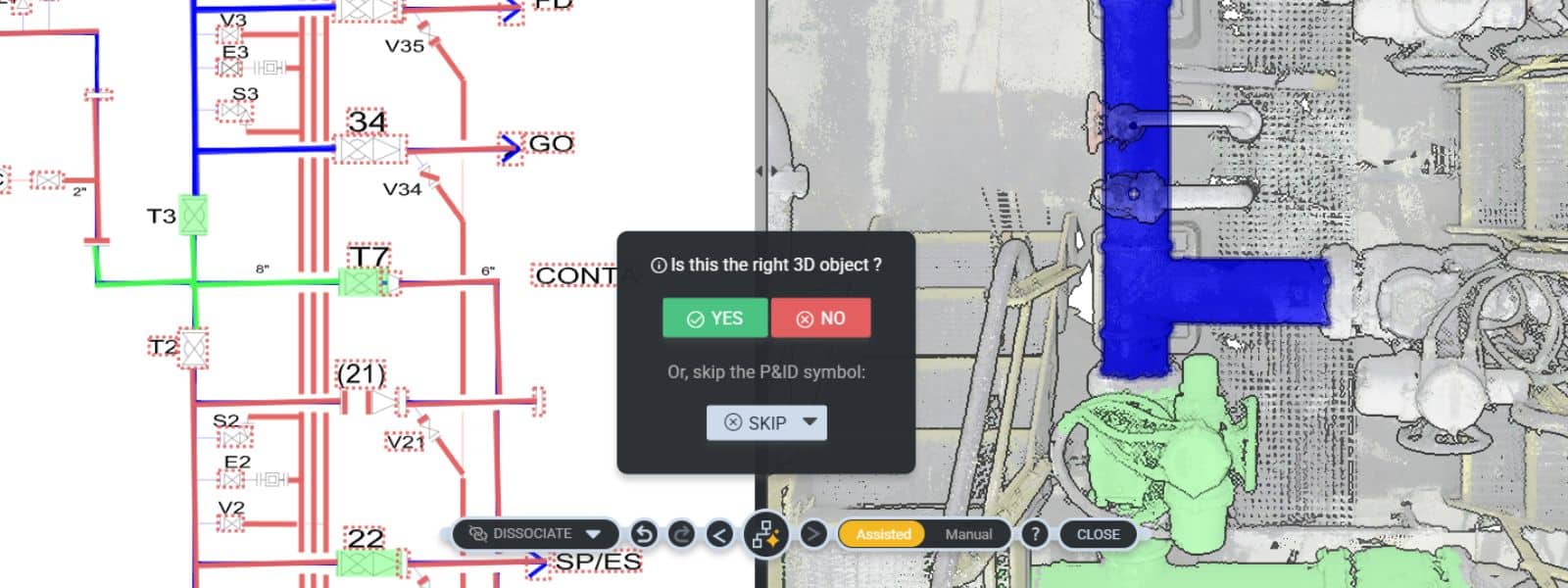

Shared Reality Copilot, the latest evolution of our AI engine, which is helping industrial operators manage piping-intensive assets more efficiently.

... read more

... read more

Shared Reality Copilot, the latest evolution of our AI engine, which is helping industrial operators manage piping-intensive assets more efficiently.

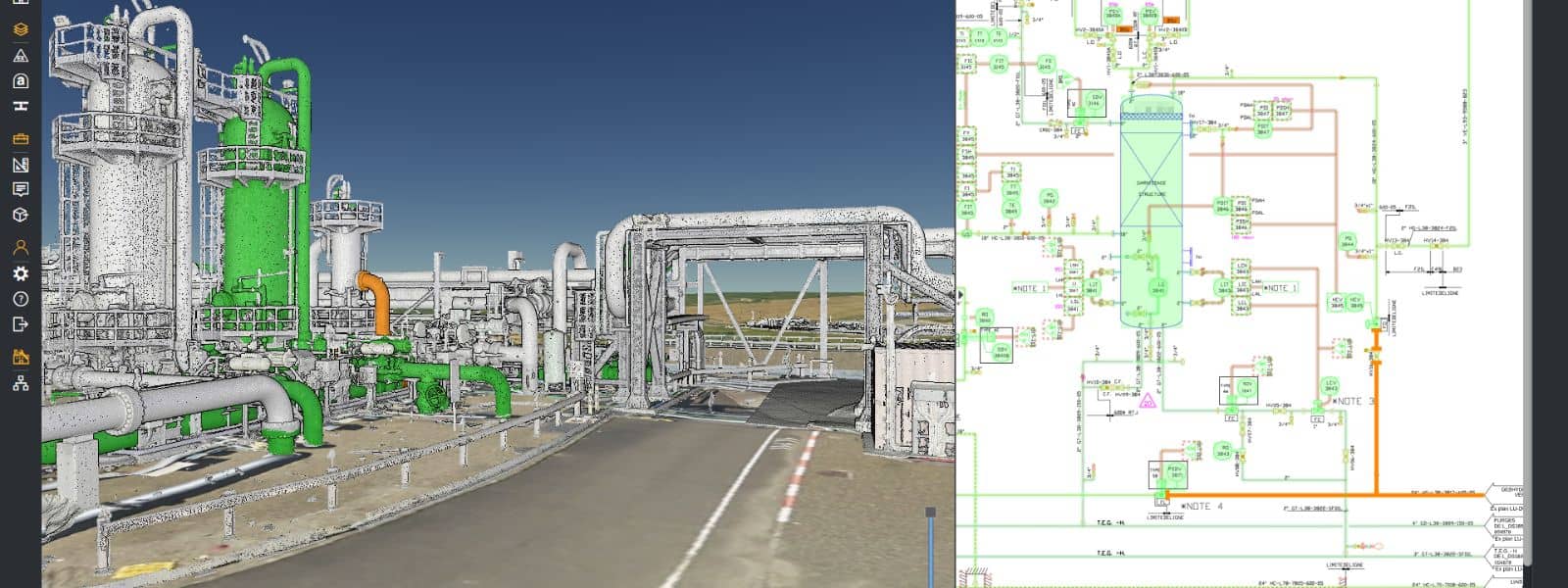

Shared Reality now supports users in linking plant components by guiding them through complex piping systems across 3D reality capture and flowsheets.

Shared Reality now supports users in linking plant components by guiding them through complex piping systems across 3D reality capture and flowsheets.

Industrial sites are complex environments where multiple teams—field workers, engineers, asset managers, executives, and subcontractors—often rely on different data sources.... read more

Industrial sites are complex environments where multiple teams—field workers, engineers, asset managers, executives, and subcontractors—often rely on different data sources. This fragmentation leads to inconsistencies, delays, misalignment, and inefficiencies.

What if everyone could see and understand the same reality?

What if everyone could see and understand the same reality?

Shared Reality disrupted the way industrial operators connect equipment within a 3D point cloud to their technical data and symbols... read more

Shared Reality disrupted the way industrial operators connect equipment within a 3D point cloud to their technical data and symbols in a P&ID.

This new capability helps you annotate discrepancies between your documentation and the actual field conditions effortlessly.

Take your team's redlining skills to the next level!

This new capability helps you annotate discrepancies between your documentation and the actual field conditions effortlessly.

Take your team's redlining skills to the next level!

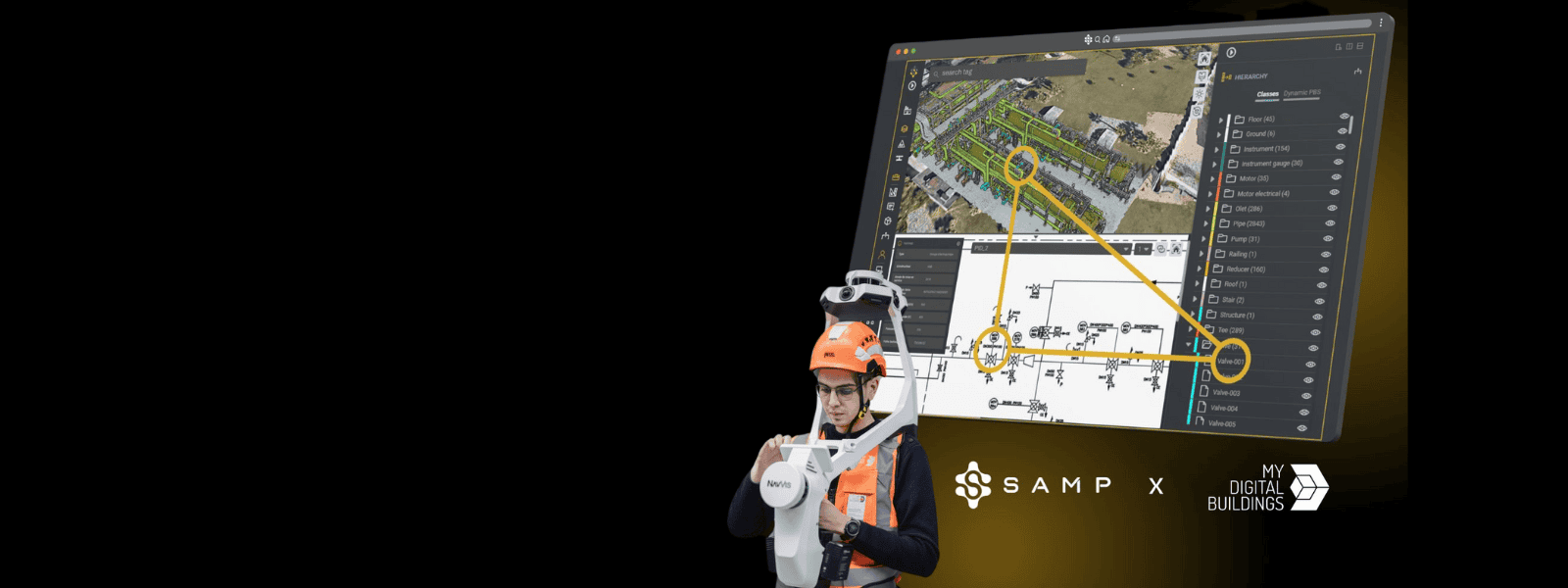

My Digital Buildings have structured their reality capture know-how into standardized workflows, delivering consistent quality in demanding industrial environments.

... read more

... read more

My Digital Buildings have structured their reality capture know-how into standardized workflows, delivering consistent quality in demanding industrial environments.

Combined with Samp‘s Shared Reality 3D workspace, end-to-end industrial facilities twinning projects become predictable, affordable and immediately actionable by all end-users.

Combined with Samp‘s Shared Reality 3D workspace, end-to-end industrial facilities twinning projects become predictable, affordable and immediately actionable by all end-users.

In this webinar, we’ll showcase how #SharedReality allows you to clean-up your existing data in a visual way.

... read more

... read more

In this webinar, we’ll showcase how #SharedReality allows you to clean-up your existing data in a visual way.

Whether your technical data is incomplete or outdated, you will discover how to use the power of visually verifying its consistency and completeness by easily linking, filtering, or colorizing it with 3D reality capture.

This approach fosters a continuous improvement cycle that keeps your teams engaged and empowered, no matter their discipline or seniority level.

Whether your technical data is incomplete or outdated, you will discover how to use the power of visually verifying its consistency and completeness by easily linking, filtering, or colorizing it with 3D reality capture.

This approach fosters a continuous improvement cycle that keeps your teams engaged and empowered, no matter their discipline or seniority level.

In this webinar replay Samp’s CEO and VP of Engineering will show you how to bring unparalleled accuracy and speed... read more

In this webinar replay Samp’s CEO and VP of Engineering will show you how to bring unparalleled accuracy and speed to your diagram updates using our new capability P&ID redlining

An industrial site is constantly changing.

What if you could keep your 3D always up-to-date, synced with your... read more

What if you could keep your 3D always up-to-date, synced with your... read more

An industrial site is constantly changing.

What if you could keep your 3D always up-to-date, synced with your data, in no time and at no extra cost!!!

Samp's breakthrough workflow within Shared Reality now allows you to have your 3D up-to-date just minutes after your work on site involving only your own teams, with zero subcontracting with full control over the data quality Join us for this webinar to witness a big reveal

What if you could keep your 3D always up-to-date, synced with your data, in no time and at no extra cost!!!

Samp's breakthrough workflow within Shared Reality now allows you to have your 3D up-to-date just minutes after your work on site involving only your own teams, with zero subcontracting with full control over the data quality Join us for this webinar to witness a big reveal