Article written by Martyn Shuttleworth, H2O Global news

The economic problems of the past few years have seen people struggle to pay bills, which leaves water utilities in a quandary. They face pressure to improve aging systems without passing costs to consumers, creating the need for new approaches and technology.

Increasingly, utilities are turning to Artificial Intelligence as the answer.

French tech company, Samp has developed a patented artificial intelligence solution to help utilities accelerate their digital twin programmes and optimise operations, maintenance, and asset management. In this article, Laurent Bourgouin, CEO and co-founder of Samp tells us how Samp’s Al-generated workspace can help utilities save money and speed up the transition of existing facilities.

Doing More with Less: The Eternal Demand

While the economic difficulties of the past few years pushed cost-cutting to the top of the political agenda, water and wastewater utilities have faced calls for much longer. Over the past few decades, regulators demanded high reliability and upgrades to aging infrastructure, forcing utilities to work more efficiently.

However, the cost-of-living crisis since the pandemic means that consumers cannot afford rising bills. News items about water leaks and sewage discharges create negative publicity and regulators impose heavy fines to show they are taking action. Water utilities have to invest even more resources in their infrastructure and maintenance, but cannot raise rates for customers.

When forced to do more with less, using Artificial Intelligence to create virtual models of a plant or network can streamline maintenance and improvements, increasing efficiency while driving down costs.

Aging Assets and Finding an Alternative

As Laurent points out, industrial facilities in the water sector operate aging infrastructure and lack up-to-date technical documentation and data. This creates losses across the entire industry, from poor asset management, lack of predictive maintenance, and what he calls a ‘technical debt.’

The traditional approaches to solving these problems usually involve expensive upgrades to infrastructure and increasing the frequency of inspections. Taking advantage of advances in computer technology, many utilities are turning to software to improve asset management and operations. This is an area that Samp is seeking to bridge.

“Samp aims at becoming the missing link of the industry between asset management and operational excellence, which often live in their own silos.”

Samp’s solution uses Al to create a 3D virtual replica of an industrial site, known as a ‘Digital Twin.” This helps utilities upgrade technical data and documentation, helping them streamline processes and reduce costs.

Samp’s Digital Twin Approach

One of the problems faced by many water and wastewater plants is incomplete technical documentation and a lack of accurate engineering reports. Engineers and workers find it difficult to locate assets and often end up working on unfamiliar equipment, which significantly increases expenditure through inefficiency.

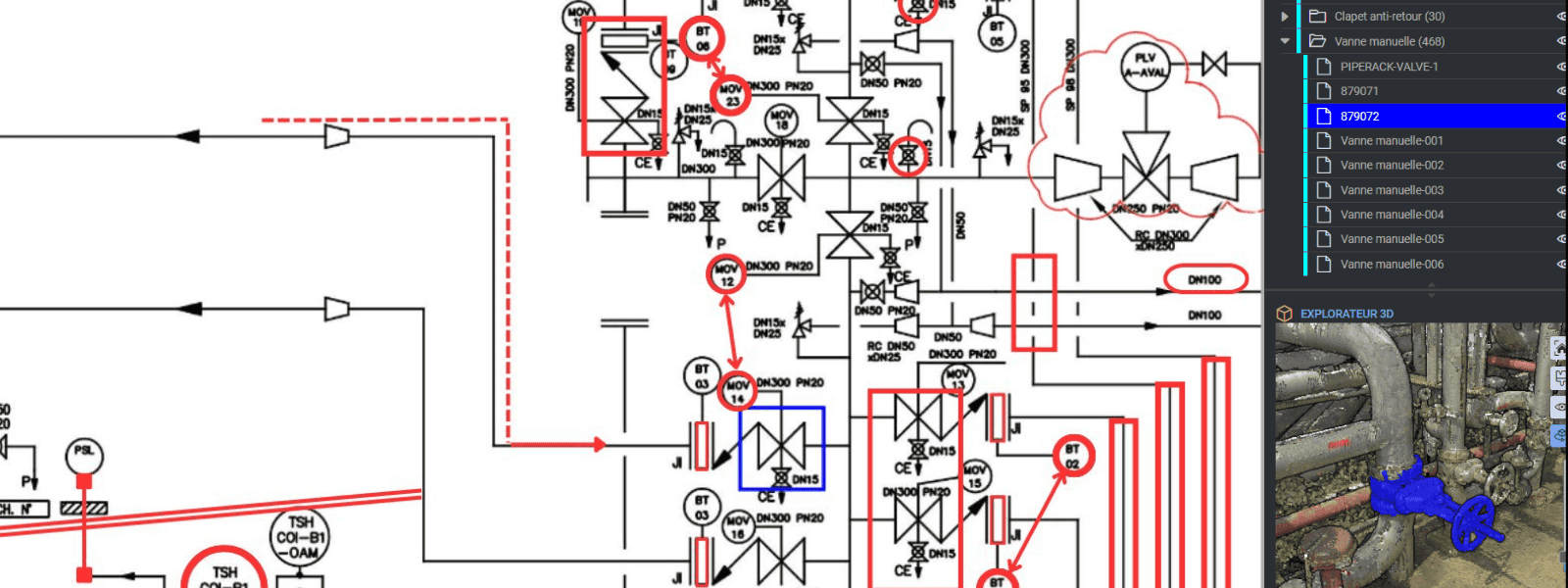

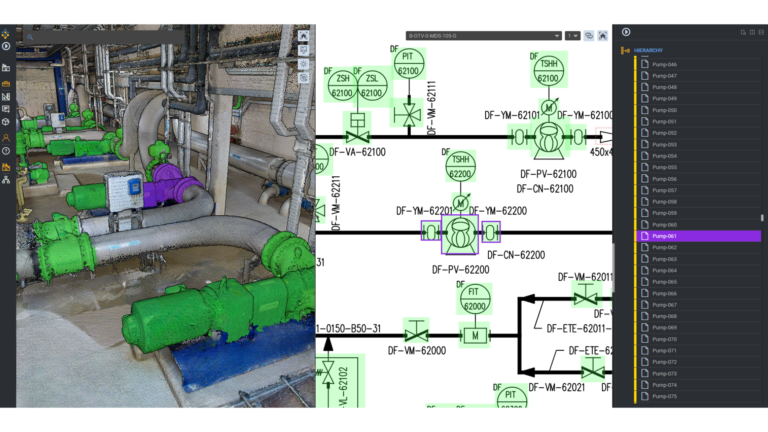

Now, Artificial Intelligence and 3D modelling provide new opportunities to lower costs across the value chain. Samp’s technology provides a digital twin of industrial facilities to speed up processes and provide the information anyone operating or maintaining the system needs. The virtual model uses Al to combine detailed recent 3D scans of plants with technical documentation and engineering diagrams. The scan provides a thorough geometric view of the plant while the diagrams provide detailed data about the systems.

Using these inputs, the Al system processes the information and, after a few days, creates a streaming workspace with a twin model. This brings together 3D and system views alongside a list of assets. Using the digital twin, engineers and field workers can retrieve accurate, field-checked data, speeding up work processes and reducing the number of mistakes.

Importantly, the digital twin benefits multiple users and streamlines workflows significantly. Site workers familiar with the plant facilities can use the 3D view to access detailed engineering diagrams quickly.

Engineers using diagrams can view the 3D context of a site, especially for locations they do not know. Finally. subcontractors with little knowledge of the site or engineering diagrams can use a search function to identify the equipment in a work order. Samp points out that:

This secured workspace can then be connected to the industrial operator’s legacy IT system to provide an intuitive and efficient way to access data from multiple systems, simplifying and accelerating their digital twin initiative.”

How a Digital Twin Helps Utilities Reduce Costs

The visual workspace simplifies working processes on existing assets by helping teams retrieve field-checked data and collaborate at all levels. This lowers risk for workers, provides trust and contractual transparency. and transforms assets by reducing the environmental impact and cost of failure.

Using systems like Samp can help utilities cut costs significantly without any decline in service:

“We cut the time for engineering revalidation and equipment isolation by 3x and shorten engineering studies for modernisation projects by 30%. For systems startup we divide preparation time by two, halve claims resolution time, and divide time for training and certification and site travel time by two.”

Digitalisation can also help with contract amendments by reducing budget slippage. Other areas include lowering the time needed for preparing work orders and for maintenance and inspections. Across the value chain, this adds up to significant savings. In addition, teams can work virtually before accessing the field, improving safety and optimising maintenance and refurbishment while reducing errors.

With this technology, the water industry can ensure that information about their assets is accurate and accessible.

“We believe that Samp can be used by a number of sectors within the water industry, including water and wastewater plants and networks, industrial water utilities, and hydropower plants.”

Samp recently worked with is SUEZ, which was looking for ways to develop resilient infrastructure.

Case Study: Samp Collaborate with SUEZ

Like many water utilities, SUEZ faces an increase in the frequency and intensity of extreme weather events. This can damage infrastructure and disrupt service and operations, leading to expensive emergency maintenance and the risk of tines from regulators. Accordingly, the utility wanted a decision-making tool that improves the ability to adapt and build resilient systems that shrug off adverse weather.

In 2020, SUEZ began a collaboration with Samp. involving an initial pilot study conducted across a number of its drinking water and wastewater treatment plants. Working with Samp. SUEZ used the digital workspace and twin to optimize maintenance procedures and target refurbishment efforts. By reducing the risk of failed components and improving workflow, asset management improved and led to significant savings across the board.

Working with Samp, SUEZ created the digital twins for its sites, linking its asset inventories and technical drawings with the 3D scans. The digital twins evolved in response to changes in the field and allowed field teams and engineers to access reliable data efficiently. Importantly, the model allowed virtual work to take place before actions in the field. improving safety.

Samp’s system optimized maintenance and upgrading, reducing the risk of equipment failure and extending the life of assets. Now, with a new agreement, Samp and SUEZ will extend the use of the technology to other water and wastewater plants across France and potentially other markets.

For Samp, the collaboration with SUEZ is part of their drive to help the water industry transform and become much more efficient, perhaps finally solving the problem of doing less with more.

“By connecting geospatial and system knowledge, Samp can help accelerate the urgent transformation of water-related infrastructure towards a better resilience and lower environmental footprint.”

This article was published by H2O Global News in its 8th issue of December 2023 magazine: Water Savings for Customers & Utilities.