The tank storage industry is no stranger to challenges, from complex site management to the need for precise data to support critical decisions. As operators strive to reduce operational risks, increase profitability, and maintain competitiveness, having a clear and accurate understanding of industrial assets is crucial.

At this year’s StocExpo, Samp is excited to showcase Shared Reality, a proven solution that enables terminal operators, midstream and process industry players to improve their operational excellence, while reducing the complexity of project and asset management.

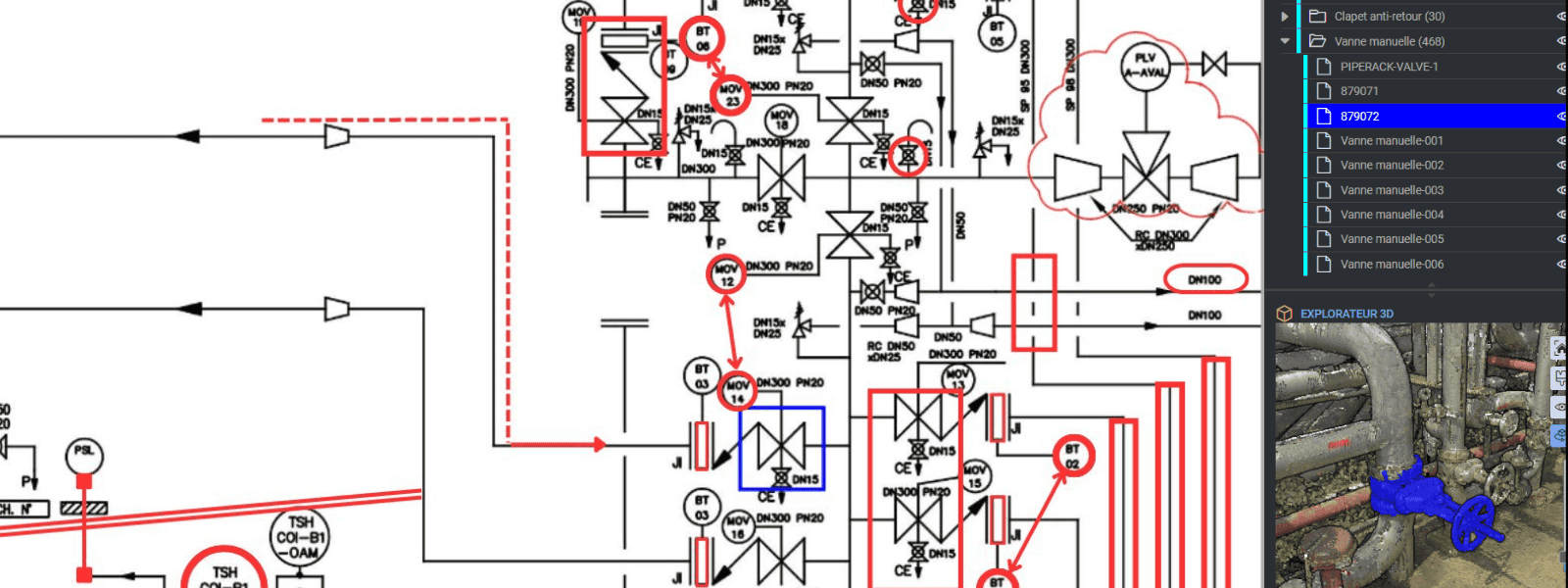

Using patented artificial intelligence and 3D technology, Shared Reality is an engaging workspace for all teams, deployed in just days. Users have an interactive access to their facilities, linking a 3D reality model of the physical assets captured on site with technical diagrams and equipment data. It helps rapidly understand the site and data integrity.

Boosting Collaboration, Certainty, and Safety

For terminal operators and the tank storage and midstream sector, Shared Reality drives operational excellence by preventing bad surprises on-site, accelerating maintenance work, improving project safety and collaboration. Whether it’s revamping, expansion, or day-to-day routines, the workspace ensures that technical data aligns with the actual site conditions.

Moreover, it serves as a shared gateway where site personnel, engineers and contractors and investment planning teams can collaborate effectively. By allowing everyone to access the most up-to-date data, Shared Reality drives informed decision-making and ensures that all operations are grounded in reality.

Fast track results and seamless integration

At the heart of Shared Reality, is AI-powered equipment recognition that allows to rapidly link the 3D representation of a piece of equipment to its technical data, giving operators a comprehensive overview of their assets.

Shared Reality can be connected with existing data sources (spreadsheets, drawings…) or IT systems (ERP, EAM, CMMS, EDMS, SCADA..), serving as a gateway to naturally retrieve, assess or update vital information.

By deploying Shared Reality in just a few days, terminal operators can reduce projects timelines, cut costs, and eliminate unexpected issues once work begins.

Proven Success Across Industries

Tank farms, terminals, and pipelines operators in the oil and gas sector have already deployed Shared Reality, including companies such as Trapil, SPMR, Elengy, Storengy, Teréga.

The online workspace is also used by other sectors, including industrial gases, chemicals and utilities, where companies like SUEZ and VEOLIA leverage Shared Reality as a key component in their pursuit of operational excellence.

Testimonial

As a pipeline operator and service provider, TRAPIL has always strived to find the best solution to its own issues and those of its clients.

With more than 70 years of operating experience, TRAPIL considers Samp as the right solution to tackle the challenges imposed by legacy infrastructure, where various data is still difficult to aggregate and keep up-to-date.

TRAPIL supports and promotes the partnership between its subsidiary SURVEY and Samp to provide its customers with the most pragmatic digital twin solution.Jean Luc Bonneville, Chief Technology Officer

Join us at StocExpo to discover how Shared Reality can improve your operations, enhance safety, and ensure seamless collaboration across your teams. Let us help you achieve the certainty and confidence you need to stay ahead in this rapidly evolving industry.

The article was originally published by StocExpo